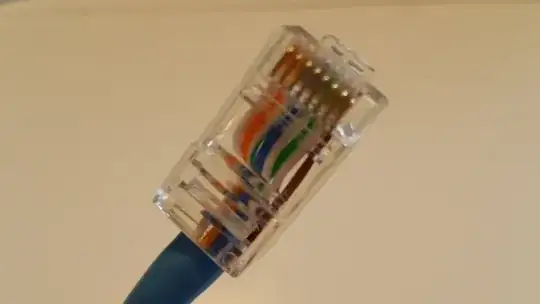

The modular plugs or what I like to call "end-caps" for Cat6 cable, I have the kind where you can push the cable all the way through then cut so you know you have proper cable alignment. I thought this would be the best way to go so I don't have to dreadfully stare at the modular plug to determine if the wiring is in the right order.

Well, what I have noticed is that it is impossible for me to cut the wiring back far enough which creates excessive amount of "noise" and crosstalk and is just a bigger issue than what I imagined. Am I doing something incorrectly or is this just a hazard of using this type modular connector?

EDIT

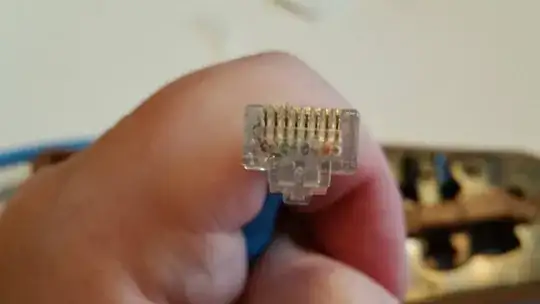

Below are images of my crimp work - looks good to me, but the cable is still not functioning!