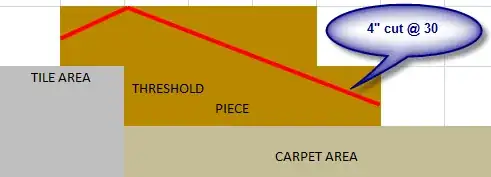

I am in the process of creating a custom threshold to go from a tiled surface down to a carpeted surface. The tile is about an inch above the carpeted floor, so I decided to make a custom threshold in order to introduce a nice slope. This should help protect the exposed tile edge from too much stress and avoid a lot of stubbed toes, which were a problem with that transition even before the added height of the new tile.

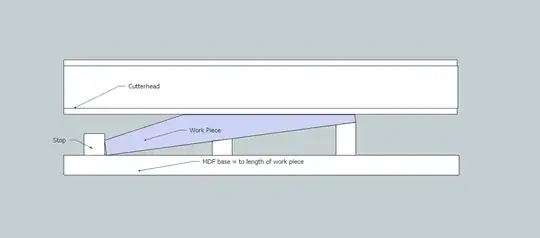

To start, I glued together two 7'-long 1"x4" boards with a 1" offset. I want to cut along the length of these boards to create a nice angle for the transition. Here's an image of a very rough mock-up of the layout.

The problem comes with the longer cut on the boards. It's about a 4" deep cut and needs to be at approximately 30 degrees (from the base). I'm not sure which tool I should use for the cut. I think it's a bit too deep for most table saws and I'm not sure if that angle would be recommended on a band saw.

Does anyone have any advice on what tool would be best for this cut? Or, if there's a better way to smooth out a 7'-long, 1"-deep transition, I'd be open to trying something else. I'm willing to buy new machinery to pull this off, so almost any reasonable suggestion is fair game.