I used to work for a company that built machines that drilled these holes (though we did it in much larger pieces, usually 3/4" to 2" thickness). It's not a hard process, it's slightly expensive, but it's doable. The process is basically as follows:

- Use two diamond-tipped drill bits to cut the hole (one above and one below);

- Use a water-jet to push water through and around the bit to cool the glass;

- Clamp the glass on a tight space (vibration relief);

- Spin the bits opposite each other at a high RPM;

- Bring the bits together and cut into both sides of the glass at the same time;

- Make sure not to smash (read: "crash") the bits together;

In the situation where vibration cannot be controlled, and you don't have an upper and lower bit, the manufacturer would typically use an ultra-low RPM (like, 20-30 RPM) which avoids the vibration. This takes longer to cut a hole, but avoids problems.

With ultra-thin material (1/8"-1/4") we would use a direct water-jet, we would literally push water at 60,000 PSI and blow a hole straight through the glass. This is done by backing the glass with a solid (usually metal) surface with a hole for the jet-stream.

You should end up with a clean-cut hole, and no scarring or scoring - minimal fracturing. We used to build these machines, and this type of scoring is very unusual and indicates a faulty machining process. Your cabinet maker likely has one of these machines quite possibly from us or a different company.

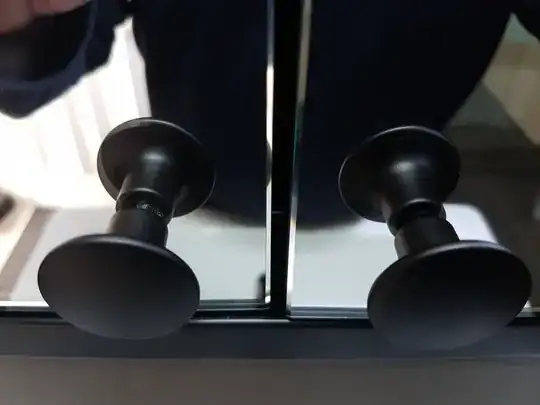

This is a defect (it actually looks like the mirror wasn't adequately cooled, so it fractured). It's plain-and-simple, this is a manufacturing defect, and you can probably convince them to send you a new one.

However, I would avoid that altogether.

While this may be unsightly right now, here's how I would fix it (usually for less than $2.00 at a nearby hardware or crafts store):

- Go to a local hardware store and buy plastic (or nylon) washers (you want plastic/nylon so that it doesn't interfere negatively with the glass, handle or paint), you want the OD (outer diameter) to be slightly larger than the total size of the issue, and the ID (inner diameter) to be slightly (but not much) larger than the bolt on the handle, you'll want a small thickness;

- Get a small bottle of whatever colour touch-up paint you like (probably black to match the handles), these plastic washers often come in gray, white or black (what you'll find depends on the hardware store), make sure it's a water-based paint (certain oil and lacquer based paints will have a negative reaction with the plastic/nylon washer or the handle), and type that is used on model cars should work fine;

- Paint both sides of the washers;

- Place the washer between the handle and the mirror to cover-up the defect;

If done right, you should be able to eliminate the defect area visibility entirely, and you should end up with a visually pleasing result. Depending on the theme of your bathroom, you may opt to get a larger OD on the washer and use an "accent colour" ('hot rod red', for example) to make it "pop" and get a more unique look.