Slow steady force has not broken the rust bond, so let’s keep the steady force add some shock. Gather these . . .

MATERIALS

- A free-standing ladder at least as tall as the post

- A piece of steel plate about an inch bigger than the opening at the

top of the post

- Duct tape

- A sledge hammer

- A 2-3 foot length of steel cable and cable clamps

- An old blanket or some heavy towels

- Eye protection, hearing protection

GOAL

The goal is to apply steady lifting force to the post and to maintain that force even if the post moves up by a microscopic amount. We’ll use the jack pulling a loop of steel cable as if it is a really strong rubber band pulling up on the post. With that steady force a constant, we’ll smack the top of the post straight down to break the rust bond.

PROCEDURE

Climb the ladder with the steel plate and duct tape in hand. Tape the steel plate securely in place over the top end of the post. Leave the center of the plate as bare steel. We want to get as much shock as possible when we hit the plate with the sledge hammer; a layer of tape would diminish the shock.

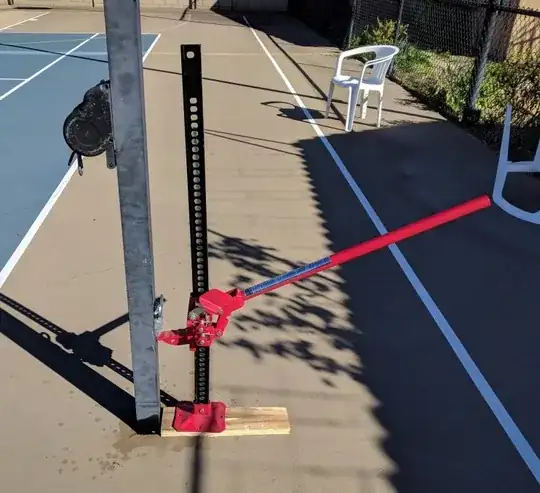

Use the cable clamps to form a loop of cable. Place the loop over the post and lower it to a point just below the spot where the jack is engaged in your photo.

Move the jack to the other side of the post. Twist the cable into a figure 8, engage the jack with the loop of cable and place the cable under a little tension.

Wrap the old blanket around the cable so that if the cable breaks, it won’t hurt anyone.

Operate the jack to place the cable and post under as much tension as possible. If the cable breaks or slips, you’ll need a better cable or clamps.

Put on your eye and hearing protection and climb the ladder with the sledge hammer. Hit the flat face of the steel plate with the sledge hammer several times as hard as you can. Climb down.

If the jack is now easier to operate, you have made some progress. Return to maximum tension and give the top of the post a few more whacks.

Repeat.

NOTES

I’d recommend against using nylon strap or rope in place of steel cable. They are too stretchy, and if the post suddenly comes loose, it could be launched out of the sleeve. A small loop of steel cable will only stretch a fraction of an inch.

If you can’t get the steel cable to work, get a helper to apply constant jacking force directly to the post while you smack it from the top. But give the helper hearing protection, a hard hat and a face shield in case the hammer or steel plate go flying. A full-coverage motorcycle helmet would work.