How should I flash this tricky corner:

This is at the junction of a 2 story section and 1 story lower flat roof, done in foam. The flashing was installed about 20 years ago, the wall below rotted and became a termite nest for various reasons, perhaps including the flashing.

This is the twin of the flashing at the opposite corner. There's no evidence of rot there, but then again, the first corner's problems were not in evidence prior to removal of stucco:

Further back showing the junction of the 1 story addition. The major water originated in a window just above here, now fixed:

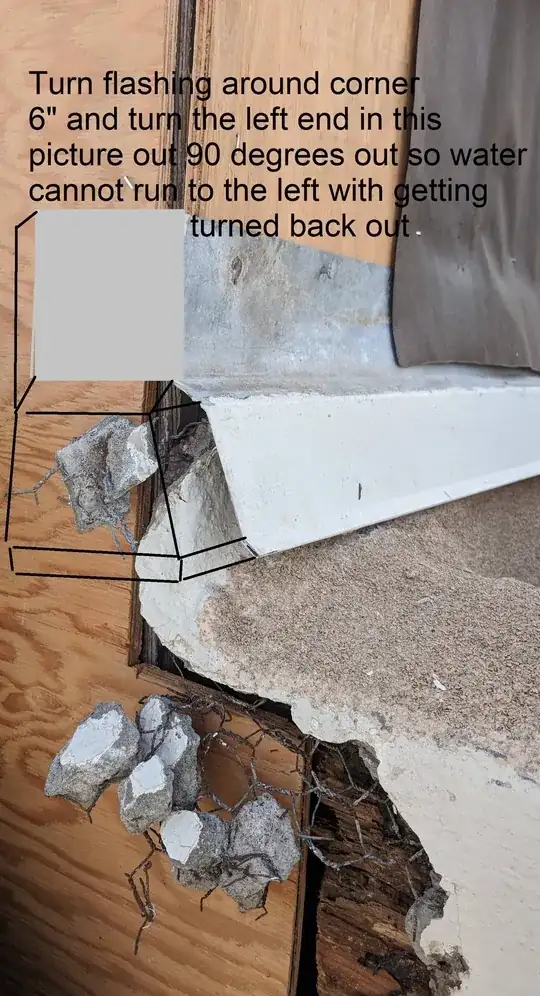

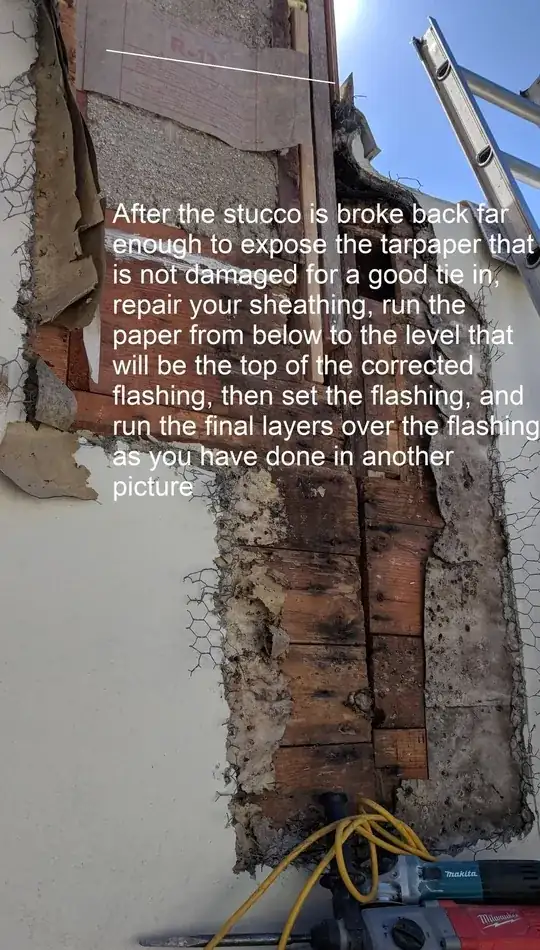

The water encouraged termites, who had probably decades to chew at the corner. This is what it looked just after removing the stucco. As is typical, none of this showed from the outside, the stucco shell showed no unusual cracks or problems:

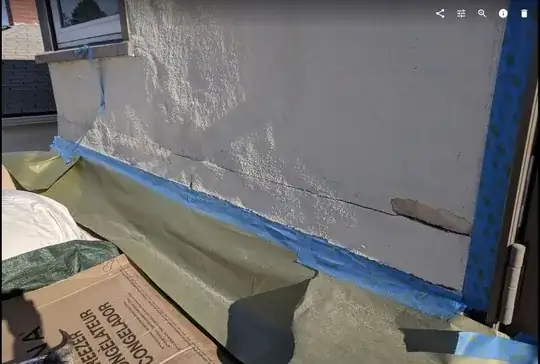

Flashing just prior to first removal of stucco. It was removed because of the crack you see:

And an overview of the good corner, twin of the bad corner: