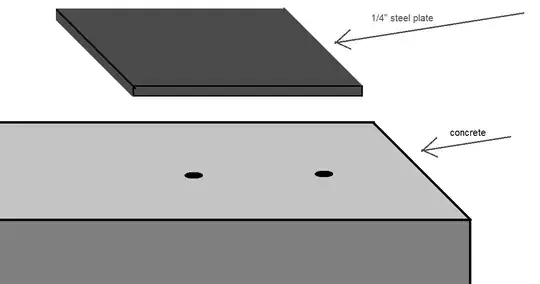

The hole spacing is more important than the location of the holes on the metal plate. Therefore, working off of option 1 from @RedGrittyBrick, this is the approach I would take using a wax pencil or marker and a carpenter's square.

(1) On one edge of the plate mark a (rough) centerline.

(2) Align this edge of the plate to the holes in the concrete, with the centerline mark (roughly) centered between the holes, and carefully mark the center of each hole on the edge of the plate. You should now have 3 marks on the edge of the plate.

(3) Carefully transfer the outer marks as two lines across the steel plate using a square.

(4) Mark a line perpendicular to these two lines and (roughly) on center on the plate. You should have three lines on the steel plate. The intersection of the three lines marks the center of the two holes to be drilled.

Repeat the entire procedure if you have multiple pre-drilled locations. Don't assume that other holes in other places in the concrete are equally spaced or centered.