A galvanized roof that leaks may have leaky nails

Tin roofs are typically held down by nails, and over the years the nails loosen and leak. The new approach is to use nails or screws with an elastomeric rubber pad, and set their compression pressure carefully. I am super fond of roof screws of an appropriate size to not overlarge the old nail holes too badly, and a "speed wrench" with bit holder to drive them both quickly and precisely. These elastomeric rubber pads give out after 20-40 years and you need to replace the roof screws.

A galvanized roof can be refreshed in place

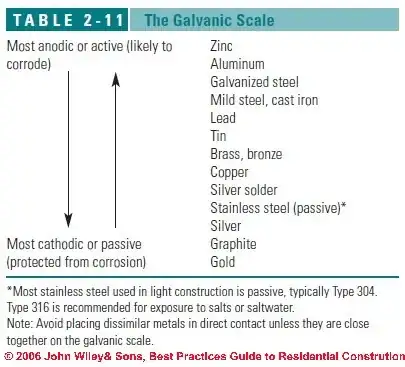

Normally I prefer heavy prep when painting, but in this case you want only the lightest scuffing - you need to remove dirt, dust and contaminants but don't remove the weathered patina from the zinc! Paint won't stick to shiny metallic zinc, you need the patina to give the surface "tooth".

Then I use "cold galvanizing compound", zinc-based "paint" which is specifically for galvanized roof repairs.

The paint is 90% zinc, and is HEAVY. I subdivide my gallons into 4 quarts so I can use the paint shaker without breaking it. You must frequently agitate your paint cup to keep the zinc in emulsion, as it wants to fall out. After about 6 months to a year, it will gain the same "patina" as old tin roof.

This stuff works direct on the metal, so if you do rust removal on a galvanized roof, you don't need another primer.

In my experience, tar is a one-way trip

Go ahead and tar a 3 inch by 3 inch square of your roof. I'm limiting it to 3" because I'm not that much of a sadist. Wait a year. Then buy a gallon of mineral spirits (don't use gas) and some nonmetallic scrapers and brushes, and remove the tar from the roof without wrecking the galvanized underneath. You will quickly (well, 20 minutes) reach the same conclusion I have: tar is non-removable in any sensible timeframe.

Once you tar a roof, it will fail again - that's why you hear people talking about having to re-tar "annually". (what kind of lousy roof needs annual attention?) Heat/cold and drying out starts introducing cracks and gaps. At first, slathering on more tar fixes that. But after a few years, the tar is so thick and congealed; the gaps are too wide; it is peeling up too wholesale - no amount of additional tar will fix it. Now you need a new roof.

Why not just remove the congealed tar? Tar is very sticky, and when the gooey fingernail-attacking, glove-ruining gunk is painstakingly removed, leaves a great deal of surface contamination that needs dozens of passes with mineral spirits. (don't use gas, or you'll forever have stink of gasoline additives wherever that roof leaks into). IME it takes about 2 hours per square foot, in my practical experience, oh, do I loathe that job.

Several of our docents advocate tar on every roof. None of the are interested in the "excess tar removal" job. Funny, that.