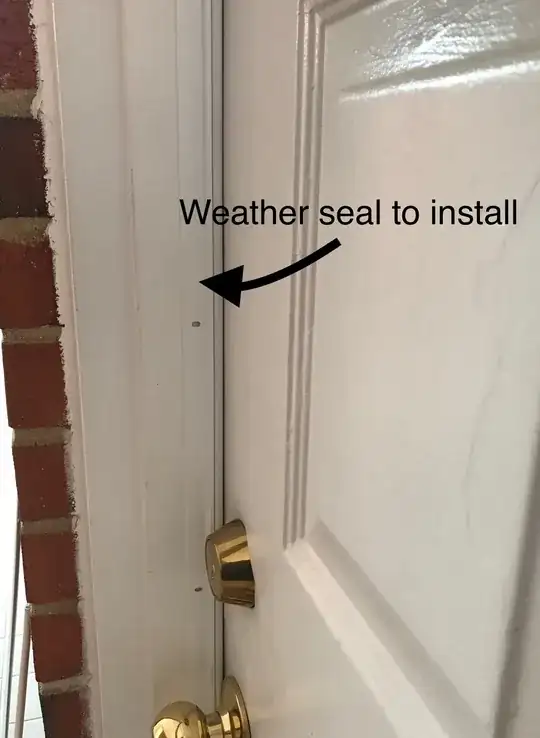

I'm trying to drill pilot holes through my exterior door frame in order to install a weather seal.

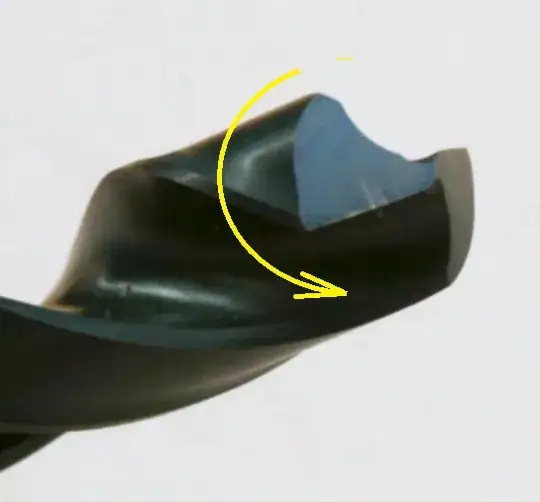

I purchased a few new cobalt drill bits labeled for hardened steel.

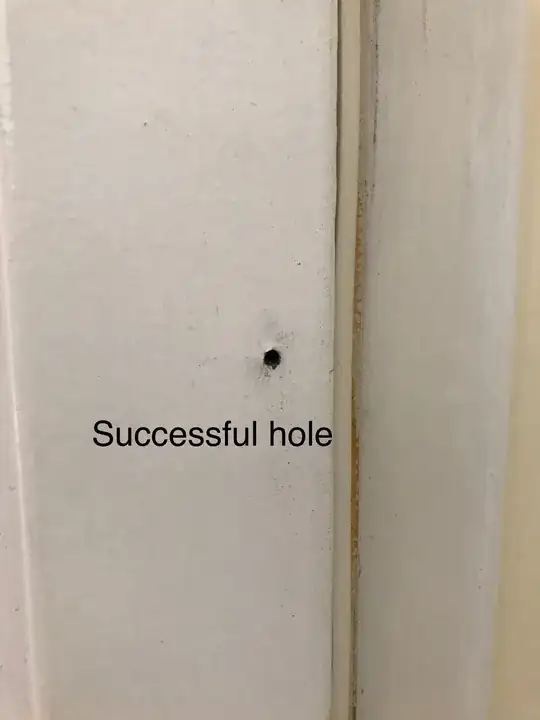

However, each new bit was only able to drill one pilot hole before losing its ability to drill holes.

After two bits, I tried applying some oil to a third new bit to keep it from overheating, and while that worked in keeping the bit cool, it still was only able to successfully drill one pilot hole. After the initial hole, the bits stopped working and could no long drill through the steel.

Any thoughts?