I opened up a hole in my concrete wall to pass a threaded PVC 2 inch male adapter. On the other side there is an aluminum metal sheet. The problem is that I hit rebar and can not change the position of the hole. I just need about a quarter or a bit less of an inch on each side of the remaining rebar to fit the adapter.

I tried drilling into the rebar with increasing bits but started going nowhere. A grinding wheel does not fit in the hole, since all I have is a 4 and a half inch disc. I don't want to cut the aluminum sheet on the other side anymore than I have already. I even tried using a hacksaw blade and tried cutting, but it's very uncomfortable and didn't do much. Even tried filling, but it's too thick.

The adapter fits in the hole, but the wider side catches on the rebar, so it over extends on the wall. I'm tempted to just grind the excess PVC.

Hole

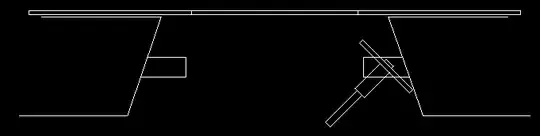

Hole with threaded 2 inch PVC male adapter in place

Other side with lock nut

Any recommendations that don't involve a heat torch to cut a piece.

Edit: Bought a Dremel 3000 and was able to cut the rebar. Took a while but worked out great. The Dremel cost me about $61 on sale at Wal-Mart and bought some discs that were also on sale. Always wanted to get a Dremel. No time like the present I guess. Here are some pics.

Thanks to all!