I’ve added a waterproof plastic baseboard. Cut the angle at the door join at 45 deg which shows a predominant gap. I could just caulk it, but it would look terrible. What would be a good filler that wont crack and can be sanded and painted?

9 Answers

You should really do a mitered return on that edge and terminate it into the wall. It will require a 45 cut in the opposite direction and a small piece, also cut at a 45 to fill the gap to the wall.

Gary Bak's answer is good. You can also do an angled return if you wish to ease the transition a bit. This involves a 22-1/2° angle on the main piece, and one 22-1/2° and one 45° on the return piece. Watch your fingers!

- 158,133

- 9

- 190

- 463

Any non-shrinking wood putty should do. Elmers, Minwax, and Durham's offer good products. You could also use a setting-type joint compound, such as Durabond.

- 158,133

- 9

- 190

- 463

I would cut a piece of wood to fill as much of the gap as possible ( can be secured with either adhesive and/or nailed into place ). You can then fill the remaining small gaps with your choice of wood putty and sand/paint.

- 165

- 1

- 7

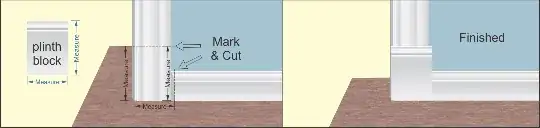

Another option is to just add a decorative base block moulding. They are available in a variety prices and styles. This would look nice and work well if you are not skilled enough to do the mitered solutions cough like me cough suggested in other answers.

Here's a link to one at a big box store.

- 355

- 1

- 2

- 11

The Right Way to terminate baseboard is without any return or diagonal cuts, running it into plinth block at the bottom of the door casing. If you want to do this, you can probably do a 45-degree cut the opposite direction on a piece of leftover baseboard material to replace/extend what you already cut and cover up the seam when you paint. While OP's photo indicates that the current door casing does not have plinth block (it just runs all the way into the floor), if there's a reason the baseboard needs to be waterproof then it might make sense to also replace the bottom of the door casing with a suitable waterproof plinth block so that it's protected too.

Short of that, you can achieve a result like Gary Bak's answer (which also looks nice) without ripping out what you've done. I see two ways to do it:

Build up the missing material with filler (I'd use acrylic resin for automotive body repair, but other materials would work too), carve a return to match the baseboard design using a rotary tool with carving bits or unpowered carving tools, and sand it smooth with the existing baseboard before painting. Or,

Prepare a short (e.g. 1-2") piece of baseboard with the mitered return as described in Gark Bak's answer, cut off just enough of the end of your work (including the whole 45-degree part) in-place, and glue the attach the replacement in.

- 1,101

- 2

- 12

- 23

I could just caulk it, but it would look terrible.

If you caulk the top of the baseboard(gives it a cleaner look) then you can caulk this side easily and it won't look out of place. A tube of basic white caulk doesn't cost a lot.

- 26,498

- 8

- 44

- 100

I would add a plinth block (as mentioned also in R.'s answer). If you have a moisture issue in this room you could get one made of waterproof material, and you will have a more finished look when you're done.

If you measure and cut very carefully you can do this without removing the existing trim (other than what you're replacing with the block).

- Choose a block that's taller than your baseboard (around 2 inches/5 cm is standard, but I've seen blocks that were both shorter and taller than that) and wider than your door trim (1/4" or probably 1/2 cm wider is standard, but you may need to go a little bit wider than that to make sure you can cover the gap left when you cut off the beveled part of the baseboard) and deeper than both. If you have plinth blocks elsewhere in your house try to find something that is similar, or if there's a particular style of trim that you're adding in this room you could coordinate with that. Otherwise, something fairly plain will draw the least attention.

- Measure your block and the space two or three times, and mark where you want to cut across the door molding and baseboard. Measure up from the floor on both sides of the casing. I would set the block in place and eyeball my marks, too, just to make sure there isn't anything wonky with the floor (but I've only done this in really old houses, where there's always something wonky with the floor). If you have to err, err a bit on the side of cutting less, since you can always cut more.

- Use a hand pull-saw or something like a dremel to very carefully cut through the trim, being careful not to mar the floor or wall. (If you have room, you might want to slide a piece of cardboard or something like a floppy plastic notebook cover between the trim and the floor.) These will be 90° cuts, perpendicular to the wall.

- Carefully remove the trim from the wall. You may want to score behind it with a utility knife, and use a putty knife to help pry it free. It's OK if there's a little bit of damage to the paint behind the trim you're removing, because the block will cover it, but you don't want damage that extends beyond what the plinth can cover.

- Pull leftover nails and clean any glue or excess paint off the wall, so you have a smooth-ish surface. Again, dings behind the block will be hidden, but you want it to be able to lay smooth against the wall so you don't want nail heads or anything else protruding.

- Set your block in place. Typically it would be centered on the casing, but you may need to have it be wider on the outside of the door (toward the baseboard) to fill your gap. If it fits, great! Attach it as you would other trim, caulk, and finish. If it's a bit too large, you can either sand the existing trim or the block (or both) so that it fits. Hopefully you won't have much of a gap, but if you do this installation is pretty forgiving of filling and caulking—one of the purposes of these blocks is to disguise less-than-perfectly-true dimensions, and to avoid the need for precision angle cuts.

- 131

- 5

The base block and miter solutions already proposed are certainly the prettiest answers. If you really want to use a filler, a coworker of mine has used Kwik-Poly. It mixes like a 2-part epoxy and will sand and work like wood once it's hard and is paintable.

- 1