I will be installing a Tesla wall charger in the garage and have a few questions about the codes and such. It will have a 100 amp breaker and it will be pulling 80 amps for 2-6 hours at a time so with that in mind I am rating my wire as "constant load".

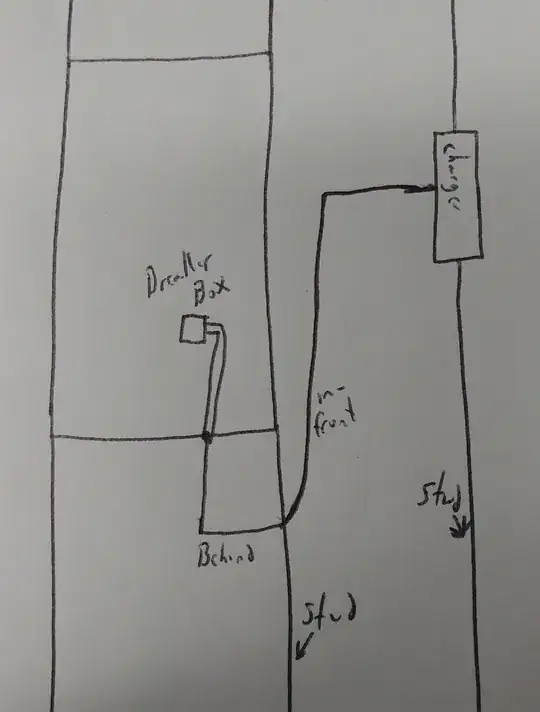

I will be installing it about 2ft from the breaker box and will run the wires partly in the wall and partly in front of the Sheetrock. Now I believe the codes call for all wiring to be in some sort of conduit when inside the wall. Can I just use that blue plastic stuff for that portion? And for the run outside the wall what is the rules for that?

Also because it would be a million times easier is there a way to go through the stud? I mean I guess I could pull off the sheetrock cut a hole and replace it. Bear in mind it's a garage and the walls are unpainted or anything just plain siding. Also if it was to stay in the wall I could easily pull it through the back of the charger just like an outlet box.

The image is a rough sketch of what I'm planning on doing.