Are there any devices or techniques to make this less painful?

Yes.

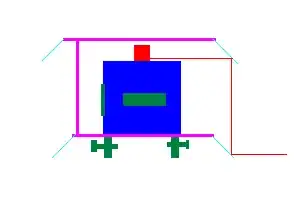

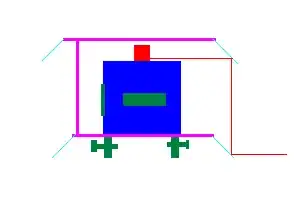

I have built myself one (it took me several attempts), but it depends on how your laser works. Mine is basically a cylinder (blue) with a rotating head on top (it can also be rotated 90° but I rarely need that), with three bubble levels on the sides and screws (green) to adjust it. I place it on the floor, adjust it until it's level and then a small rotating head (red) reflects a laser ray all around, creating a flat "plane" at about 10 cm from the ground, which as you say is really awkward (why they didn't think to put the rotating head below is beyond me).

What I did is I took a Plexiglass disc (fuchsia), with the legs drilling through, so that it's flat against the cylinder and coplanar with the laser. A second disc is mounted on top with three clear Plexiglass columns. All around the upper disc are several small mirrors at an angle of 45°, that reflect the laser down. And the second disk also holds several small mirrors that reflect the laser horizontally. My "laser plane" is now about one millimeter from the ground. Actually it's no longer a plane, I have two "fan" interleaved planes at about 10 cm distance.

(I have long hoped to find two sections of conic chromed steel cylinder with an angle of 45°, or two steel dishes or bowls with 45° sides, to replace the mirrors with a continuous construction (thus getting a whole plane at ground level instead of two "sliced" planes), but wasn't able to find them anywhere. I've also thought I could try and build myself one with thermoplastics, but for my needs, the small mirrors are enough. The only drawback is that now it's difficult to reach the adjustment screws with my fingers, and I now need a screwdriver).