I have a tripod head that is made of aluminum. In the head there is a small hole that houses a small screw that secures a quick-release plate. After some time the hole stripped and the screw no longer holds. I suspect that there is no simple way to fix it, but in case there is, I wanted to see what you guys think!

8 Answers

Depends on the size of the screw and how much material you have to work with. If this is a clamp bolt, cheap tripods use screws going directly into the casting. Quality units either use a captured nut, Nyloc nut and eccentric toggle or a tee-head bolt with threaded knob.

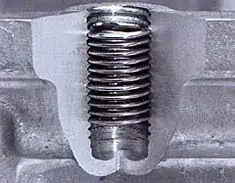

If this is a plate with a fair amount of metal surrounding the hole and it's deep enough, I would get a Heli-Coil kit. With this kit, you drill the hole oversize with the supplied drill, use the supplied tap and then the tool to install the helical insert.

Another thread repair is Keensert which, if you have yet more metal because it's a larger device, a locking insert that doesn't require delicate use of Red Loctite to keep it in place.

All the above probably are not recommended in the case that the threaded hole is in a casting that doesn't have spare metal, so the previous recommendations of drilling oversize and tapping for a larger bolt might be the best. Which might not be a solution if the threads are common photography standard attachments between devices.

- 11,431

- 1

- 29

- 44

The two options are:

Re-Thread the hole with a bigger screw (dont force a bigger screw into a damaged site). Use a Reaming/Tap tool to increase the thread size to your desired size... (also, in order to use the heli-coil) you will need to ream/tap the hole.

Helicoil - places an insert into the site to reduce the thread size once again. you will need to match the size and thread pattern with your current screw. so i suggest taking the screw with as a sample.

- 3,422

- 6

- 20

- 38

Aluminum is a soft metal and screws stripping is very common. Since I don't know of any way to make a striped hole smaller, short of welding in new metal then drilling and tapping, the only solution is to make the screw larger. If you have a #6 screw now, use a #8 now. Simply replace the original with the next larger gauge. BTW, that is not giving up, it's fixing the problem in an economical way.

- 58,628

- 3

- 87

- 168

If the screw has stripped out the treads in the hole it will go into, there is little choice. The hole is now too large, for a screw that is now effectively too small. You cannot simply "fix" this without some work.

You can use a larger screw, thus one with a larger diameter. This will require you to re-thread the hole for the new screw diameter. You might have to first pre-drill the hold to enlarge it more, depending on the tap you will use.

You could fill the hole completely, using an aluminum "welding" material. In theory, that material can now be re-drilled and then tapped for the screw thread you have. Be careful though to not overheat the aluminum body.

In either case, it will take some effort to repair.

Nutsert is a thread repair system that restores or installs threads in just about any material and any thickness. The threads are steel so they last through repeated use. They are available at "Fastenal" dealers/stores. There are two types flanged for thin materials and flangeless for thicker materials. The flanged units are similar to a large rivet with threads where the usual pin would be. While a rivet expands by pulling the pin into the rivethead, nutserts use a threaded insert that expands the insert and is then removed leaving the threads intact. I wouldn't be surprised if your local dealer would demonstrate how they work on your tripod.

- 11,667

- 1

- 21

- 33

I had the same issue...as a girl I took clear nail polish and slathered it around the screw. I waited a few min then attempted to screw it back in. It still wasn't 'solid' but I turned the fan on low and that seems to have dried and tightened the Polish and it now works just fine

- 11

- 1

use a tiny bit of solder and soldering iron, if the stripped threads is just a small amount of play just use super glue or super glue gel. this will tighened up your threads for the screw to grab, easy fix

- 1

You might try this:

http://www.amazon.com/Loctite-Form-A-Thread-repair-kit-grey/dp/B000WSEUII

There are also other brands of epoxy thread repair kits.

For a range of solutions see: http://www.repairengineering.com/thread-repair.html

- 11