(edited with additional info re. header)

We are removing a couple of load bearing walls as part of renos in our home. The engineer specified a W8x21steel beam to replace the load bearing wall. The floor joists are 2x10.

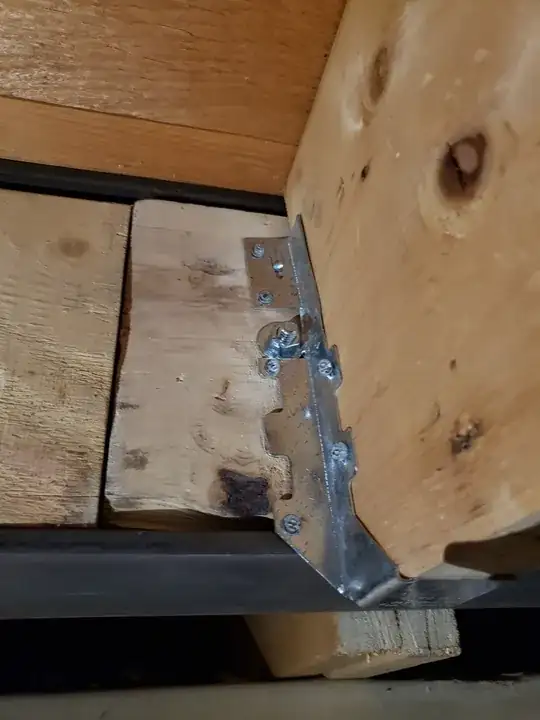

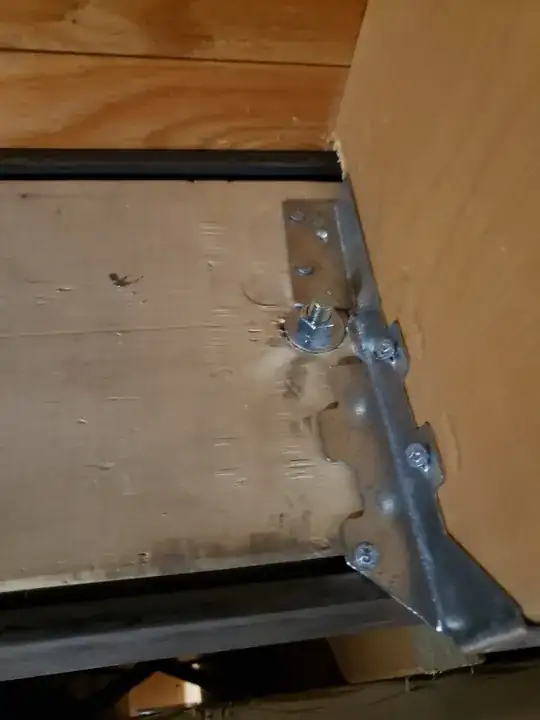

It appears the contractor put the bolts into the "header" (not sure if that is the right term) in the wrong place (not enough space between bolt and joist). He then cut some of the joist hangers to make them fit. This has been done in at least 4 out of the 10 hangers that he has installed.

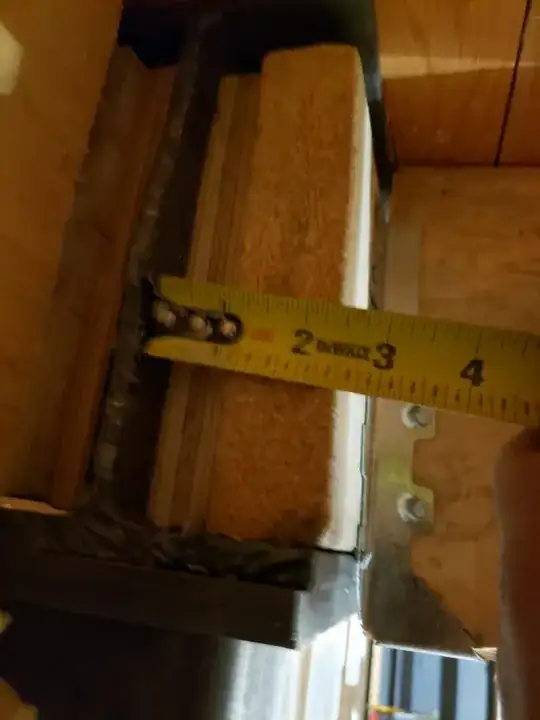

Also, he used 2 1/2" layers of plywood plus a 2x8 as a header in the flange of the steel beam (see picture below)

Questions:

Has the integrity of the hanger been compromised by him cutting out part of the material?

The hangers he used are Simpson Strong Tie LUS210Z. Are these the correct hangers to use in this application since the beam is shorter than the joist by 2" and the lowest nail barely goes into the wooden

The contractor has used N10dhdg Simpson nails (.148" x 1 1/2"). Are these the right nails to use? The Simpson website specifies that common 10d nails (.148" x 3") are used with this hanger.

Is the use of plywood + 2x8 as the header acceptable or should this be replaced with a single 3x10 cut to size? Should we use 2 1/2" nails into the header?

Per the simpson website https://www.strongtie.com/facemounthangersssl_solidsawnlumberconnector/lus-hus-hhus-hgus_productgroup_wcc/p/lus.hus.hhus.hgus

"With 3x carrying members, use 0.162" x 2 1/2" nails into the header and 0.162" x 3 1/2" nails into the joist with no load reduction. With 2x carrying members, use 0.148" x 1 1/2" nails into the header and 0.148" x 3" nails into the joist, reduce the load to 0.64 of the table value."

Is this ok and if not any suggestions on how it can be corrected?

Thanks!

Added view of header inserted into i-beam