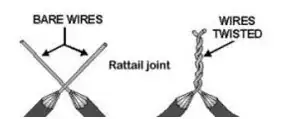

I was changing a switch in my house when I found a number of connections in the electrical box that were soldered rather than secured with a wire nut. The solder joints look very well done, the conductors were twisted together nicely and the solder itself was nicely done. It was not some oxidized amateur mess. These joints were then wrapped in electrical tape.

Is that something that need to be concerned about? Would it count as being up to code on an inspection?

I am in rural Minnesota, outside city limits, in an un-incorporated township. I do see several inspection stickers on the breaker boxes in the house, so something was inspected at one point.

Update: Just to add a bit more context. The house was constructed in 1961 and was a Gold Medallion home and as a result had lots of fancy electrical features for the day. Much of that original wiring has been replaced with modern NM cable, however the switch I replaces was on an older circuit with wires that look similar to Romex but have a braided outer sheath and instead of a single ground there a several smaller grounds that are wound around the the other wires.

The solder joints in question were on both types of cables in the box. So, they would have been done as part of later work. One of the previous owners was big into Ham radio, this junction box was right outside his radio room. In another conversation someone suggested that this was done to reduce interference, could that be a thing?