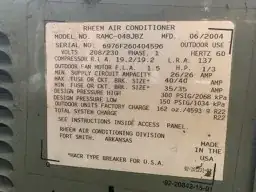

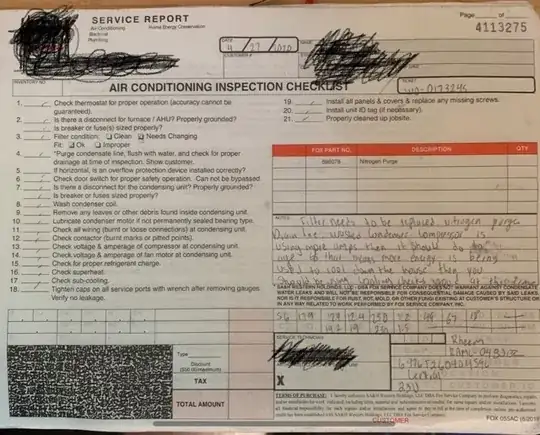

Have a 2004, Rheem, Model #: RAMC-048JBZ; R-22 refrigerant. We live in Central Texas, very hot 5 months a year, we use the AC probably 7/8 months a year. Have had annual maintenance performed since we bought the place in 2016. Just had it serviced and technician advised us to consider replacing the whole unit because (after cleaning coils, checking refrigerant and capacitor): - Compressor is overtaxed. At 65 deg. inside and 71 deg. outside, compressor is already pulling 12 amps. R.L.A. is 19.2. So this doesn't bode well for our upcoming 100 degree days. -Disconnect fuse and housing mounted on outside was partially melted. This may explain, last year, a blade on the condenser fan partially broke and continued to spin inside the system until I heard it and shut it off. I then installed a new condenser fan last summer. -Coils are clean; refrigerant remained charged over past year; capacitor is, apparently, good.

Is it time to replace this entire 16 year old unit? Or should I try to replace compressor myself? Compressor retails around $1300. Will be getting another opinion/estimate from another company.

Thanks yall.

UPDATED PHOTOS OF DISCONNECT BOX AND FUSE