Question:

How much weight can a 3/4" x 8" lag bolt hold when drilled in half way? What about other lengths and thickness, and percent drilled in? Is there some sort of formula to calculate?

Optional Background:

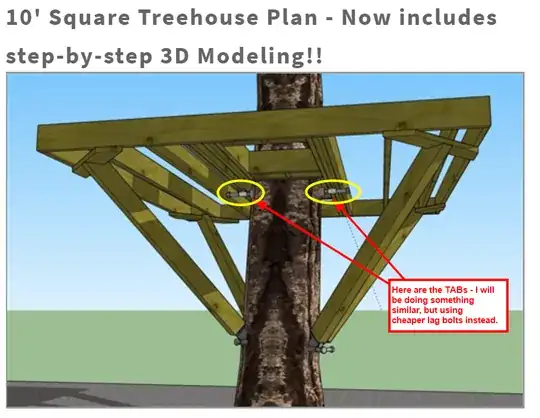

I'm planning on building a modest treehouse, on a tree whose trunk is oblong and whose long sides are probably not exactly parallel to each other. Because of this, I had the idea where instead of using lag bolts to screw in the joists on those oblong sides, I want to screw the lag bolts independently into the tree, and have the joists sit on top of them. This way I could have a perfectly square floor even if the sides of the tree are not parallel - it gives me some flexibility. It's a similar idea to a TAB (Treehouse Attachment Bolt), but a much cheaper version, as TABS can cost from $200 - $400 each! I want to make sure the bolts can hold enough weight when screwed in partially. Here's a screenshot of a similar plan where they're using TABs (highlighted in the screenshot - I will be using lag bolts instead of TABs - and I'll probably have 2 on each side):