We are looking to install two NEMA 14-50 outlets for our kids to charge their electric cars, and I'm confused about wire choice. I thought I understood the correct wire to use, but then ran across a Tesla document that said something completely different than I was expecting.

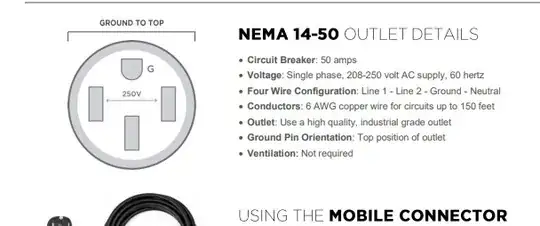

Tesla has published installation instructions here that recommends 6 AWG for up to 150 feet. Here is a screenshot:

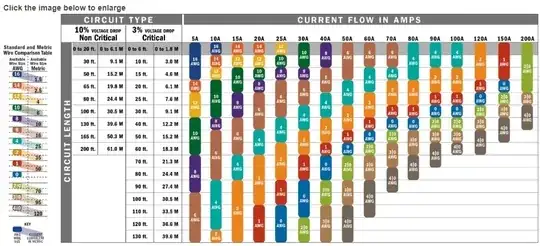

However, when I search online for AWG charts, I find many results that all agree with each other, such as this one from here:

Using these charts to spec out a 150 ft circuit, even allowing for a 10% voltage drop, I see that I need at least 1 gauge wire for 50 amps. If I want a 3% voltage drop (which I assume an electric car would need), then I should be using 4/0 at least. According to this chart, 6 gauge wire would only be sufficient out to 15 ft for 50 amps (or 50 ft if we allow for 10% voltage drop); neither of which is close to the 150 feet suggested by Tesla.

Given the clash between my internet-educated understanding, and Tesla's official publications probably written by electrical engineers, I have a feeling that the incorrect party might just be me. How is my understanding incorrect, and what gauge wire is actually needed for a 50 amp 14-50 outlet?