Since no one else has suggested it, a bandsaw would work well for this curve.

Depending on how big of one you have access to, you might need to increase the size of the material support plate. And, in this case, having a wide blade would help prevent wandering. You could easily rough it in fairly closely with the bandsaw, then use a large spindle sander or belt sander to finish it off.

You could even build a jig to help with the cut, similar to how people cut round table tops with a bandsaw, except that the scrap piece is the part you want to keep. This is just one example of a jig I found, but there's many out there to find.

https://www.youtube.com/watch?v=N6_2h-vo0jA

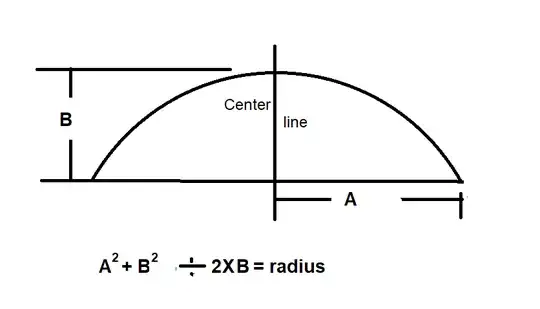

To find the center of your circle/arc, draw a straight line between any two points on the arc, then find the exact middle of that line. Starting at that midpoint, draw another line at a 90 degree angle towards the center of the circle. Repeat the process again and where the 90 degree lines cross, that's the center. Repeat the process again to be more accurate, and to find out if you have an ellipse (oval) or an actual circle. With an ellipse, the 3rd and later 90 degree lines won't cross at the same point as the first 2. To make sure that you aren't accidentally creating a false center, make sure you don't reuse any points on the arc.

https://www.instructables.com/id/How-to-find-the-center-of-a-circle/

This is likely how a carpenter or handmade woodworker would make this curve. Not everyone that would do this kind of cut is IKEA (as mentioned in another Answer) and have access to a CNC router. I built my own 4'x8' capacity CNC router, but that's beside the point.

I realize not everyone has a bandsaw or large sanders, so you might want to find a local makerspace to see if the have that stuff. Makerspaces often have pretty good woodworking tools, but that varies with the organization. I've seen makerspaces that just have 3D printers or just have computers for internet and other IT related uses.

You might (but not likely) be able to find someone willing to help you with this one project, but becoming a member will give you access to all that equipment (based on their rules for it all). It'll also give you access to more build space as well as lots of people to help you figure out problems and even help with your projects. Yes, they will be willing to help other members (depending on their time and experience), even if they won't help the random walk-in.