Unless something is clogged, this should work fine (assuming appropriate slope on all lines.) The vent should be 2" for a 4" line, and is only draining the tub (2DFUs) which is half the permitted load wet venting. The vent loading (shown) anyway) is at most 8 DFUs (depending on toilet flush size) and while that could (easily) use 1.5" on that basis, it can't wet vent more than 1 DFU at that size and it's also not "at least half the size of the drain pipe" so it would be undersized/illegal. There is an error which your plumber failed to mention, however.

When you are not showering or draining the tub, that is a dry vent (yes, it's technically a wet vent all the time, but in practice, it's dry except when the tub drain is flowing water.)

If you (or plumber) have not already snaked the tub drain all the way to the main line, do that. Snaking the vent is also advisable, as it may be clogged away from the tub connection or on it's way to the roof. Snaking the main line to whatever point it appears to work well is also advisable. Unless something was done that you/your plumber did not mention, I see no sign that it was actually checked to be clear in what you have reported - just that the plumber stood on the roof and observed it not working.

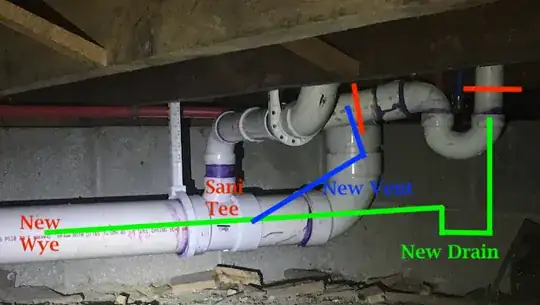

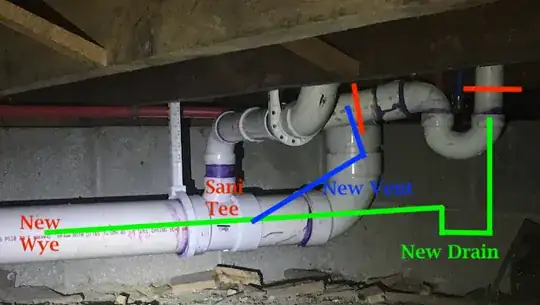

The thing that is VERY wrong with it (not mentioned in your quote) is that a sanitary TEE is being used incorrectly to join a horizontal drain - that should be a WYE, and if you are replumbing, you'll want to fix that. You can use a "combo WYE" or a "WYE and a 45" in that orientation, or you can use a wye in the normal (to the side) orientation for the drain connection.

Under IPC rules it's generally accepted (or not forbidden) to use a sanitary TEE that way FOR A DRY VENT ONLY. Some dispute that use being acceptable, and other codes may actually prohibit that use - IPC prohibits that use for a drain or wet vent connection. A WYE is always acceptable - for a dry vent, pull the WYE up to at least 45 degrees above centerline, or run it right out the top.

If you wanted to change this around and separate the functions as proposed (which I doubt will help, unless one of the pipes you cut and replace is full of gook that you should have gotten clear via snaking) you're in for a signficant bit of work - dropping a new fitting into a main line means getting upwards of two inches of motion on it, and under IPC rules "saddle tees" are illicit (don't know what rules you are under, code-wise) though you can use PVC repair couplings (and pray they don't stick before they are in the right place) or rubber couplings to have a "removable section" to give you the working room. Here you might just yank the toilet and unscrew its flange to get the working space you need.

The other distinct possibility is that the main line is not properly sloped all the way to wherever it goes off to the left side of the picture - a low (or high) spot in the line can cause all sorts of trouble with proper drainage. A competent plumber should have noticed that, but I question your plumber's competence (or perhaps honesty) if everything did not get verified as clear by some means (snake, drain camera, whatever...)

If seeking to "separate the functions" (or simply make it "correct to code", at least IPC) the most minimally invasive method I would envision is (after thorough pipe cleaning):

Cut off (leave stubs) the tub trap. Under IPC rules the distance from the fixture outlet to the trap weir "cannot exceed 24 inches" vertically, which means you can be that far, if needed. Extend the tub drain down to reposition its trap weir (the waterline in the trap) 1/4" per foot it's away from the main line higher than the centerline of the main line where you will connect it. It looks like you probably can do that within 24" vertically of the tub, by eyeball. You're looking to run it under the vent line, which you will leave alone other than throughly cleaning it.

Cut in a 4x2x4 WYE (i.e. a 2" sidearm from the 4" line) rolled just enough above centerline to meet that trap (ie, rather than set the WYE dead level, set it so that it connects at the right slope for the drain.) Connect a 2x2x2 (or 2x1.5x2 if the tub is 1.5") WYE "more than 4 pipe diameters downstream" (8" for 2" pipe) from the trap exit on the new drain line and plumb that to the (now dry-vent only) former tub entry to the dry vent line - that vents the tub trap directly, since you have the connection sitting there. Wet venting it via the main line back to the dry vent is likely acceptable, but this is better, and costs very little in time, effort, or parts.