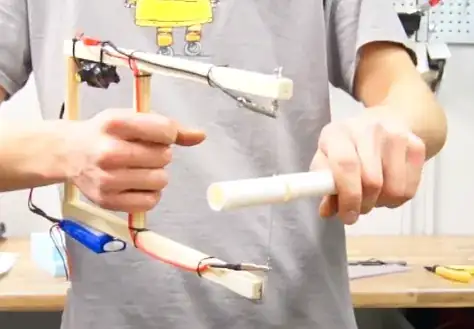

The top of this pipe is gouged where it needs to seal with the new shower base. I need to trim off a few inches from this pipe so I can glue on a clean piece. the hole is 10" square. The pipe diameter is 2 3/8".

What's the best tool I can use that will fit in the hole.

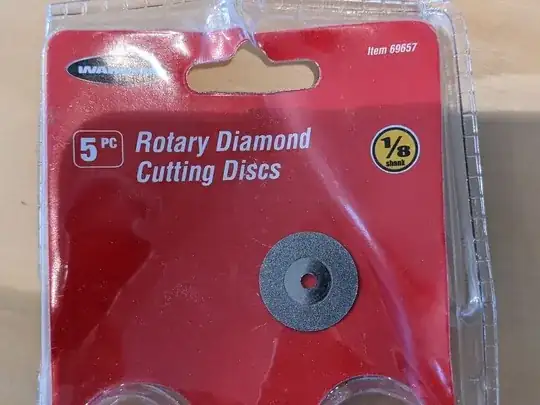

Follow up, I ended up using the dremel with a diamond disk. I used a hose clamp on the pipe to keep the cut straight. Lot of great suggestions but this tool I had so no need to run out to the store.