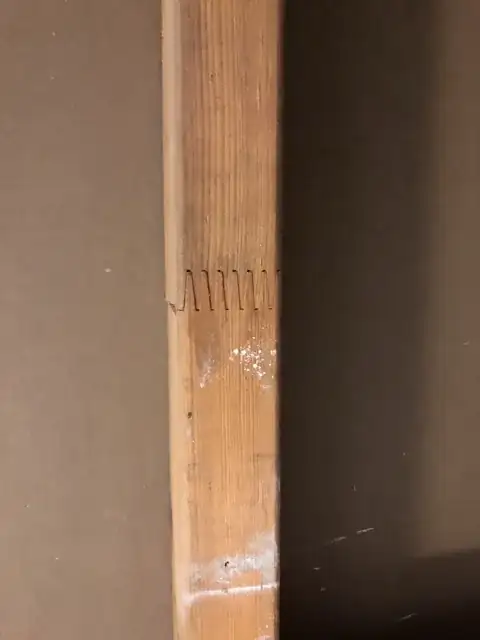

Those are called "finger jointed studs". These joints are weaker than regular 2x4 or 2x6. I do a lot of woodworking and when gluing boards together (for like a table top) the glue joints are actually stronger than the wood itself. But for some reason, that's not the case with finger jointed studs, they are just much weaker than the intact 2x. That and the alignment issue between the pieces make this product junk if you ask me.

The contractor that built my house started using them for interior walls. Some of the joints were off by as much as 1/4", which would have made sheetrocking much more difficult. My plumber said he hates them because unless you brace the stud when drilling, they'll break at the joint. To demonstrate, he got a short length (about 4') with a joint in it, elevated one end on a 2x and then proceeded to kick down on it. It broke right at the joint.

After a few interior walls were built with that crap, I inspected and found many cases where the joint wasn't at all even. I told the contractor to tear those walls and not use that crap anymore. He didn't like me for it, but later, when he used them on a project for himself, he admitted they were crap.

To answer, since they are already in place I wouldn't worry about it. The vertical load capacity isn't affected, esp. not an issue in a non-load bearing wall.

Sorry for going off like this, but finger jointed studs are just not a good product.