So far, I've only seen other questions around here about galvanized pipe or duct, so here's a new one for you all!

I'm trying to patch up holes rusted through a telescope observatory's dome. The panels themselves are, according to documentation, Galvalume; the rest of the structure, g-90-grade galvanized steel.

I'm not a welder nor do I expect the community college has funds to hire one for this job, though I understand that would be the most ideal fix. I also never heard back after asking Facilities if anyone on staff had repaired galvanized metal before.

So, I think this is gonna be a "DIY" job. My thought is to repair by sanding/grinding away the rust, applying some sort of metal filler putty, and then painting over with a galvanized-approved paint. The dome is incredibly difficult to disassemble (i.e. we need to rent a crane), so I'll have to do this in-situ... so, products need to be OK with high humidity and possible rain (though I can cover with a tarp) while curing/drying. This is in Hawaii, where there's equal part bright sunlight (read: intense UV) and rain exposure, salt breeze (one mile from ocean), and no chance of freezing.

Q.1 - what sort of filler putty to use? Permatex makes a 25909 "Liquid Metal Filler", which claims excellent adhesion to galvanized. 3M Bondo Gold also claims adhesion to galvanized. Weirdly, I emailed 3M and they stated Bondo "is cosmetic only, not an adhesive" and that they "do not manufacture/market a product to meet your needs". Hmm.

I figure that I'll need a fiberglass or polycarbonate patch to reinforce the inside of the larger holes (well, definitely the couple of 3-inch totally-rusted joints that might just need to get chopped out).

Q.2 - how large of a hole can I get away just filling in, before needing a reinforcing patch? Half-inch? There are two spots that are just pinholes right now, but they're directly overhead (the sliding shutter tracks have foam insulation that's above these points), but once I sand them down I expect to have to patch a larger area.

Q.3 - Is there some reason to not use a "cold galvanizing" spray-can paint to finish over these repair areas? I am looking at Rust-Oleum 1685380, which states to not use another primer or topcoat when used on galvanized. It says it is an epoxy ester product.

Thanks for your time and any past experience!

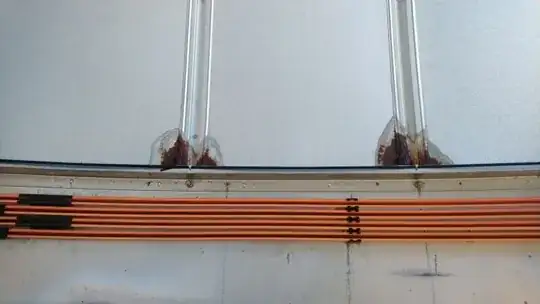

Edit: Just found I could add pictures. Here are a couple to help illustrate:

The bad seams, from inside:

The bad seams, from outside:

The bad seams, from outside:

Pinholes, about 12 feet overhead:

Pinholes, about 12 feet overhead:

The worst area, plus surface rust:

The worst area, plus surface rust: