For soundproofing applications, they make acoustical putty that you put around the electrical box. However, what if you can't get behind the electrical box? In my case, I have a wall floating on hat channels about 3" from the studs. The electrical box I will be using is an old work box with a clamp that allows the box to be fastened to the drywall rather than studs. This means that I will not be able to get to the backside of the box to apply the putty. I though about putting it around the outside of the box before sliding it through, but that doesn't seem like it would be very stable.

This leads me to me idea of putting the putty on the inside. I uploaded pics of a mock application. The outlet fits well and I think there would be plenty of room for the wires. I know next to nothing about electrical, though, and I worry about not accounting for things that might not play well with the putty.

Does anyone advise against this? I hope not because it's really the only way I can do this.

Update:

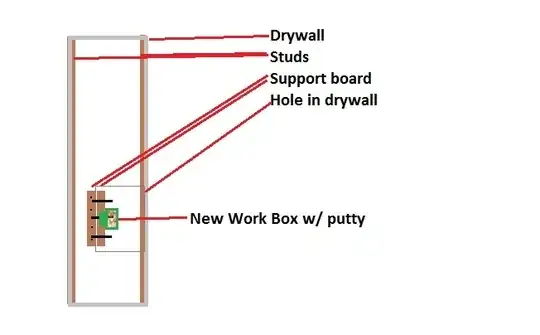

Here's what I ended up doing. At first, I had a hard time understanding Evil Greebo's diagram, but I think this was the general idea he was conveying.

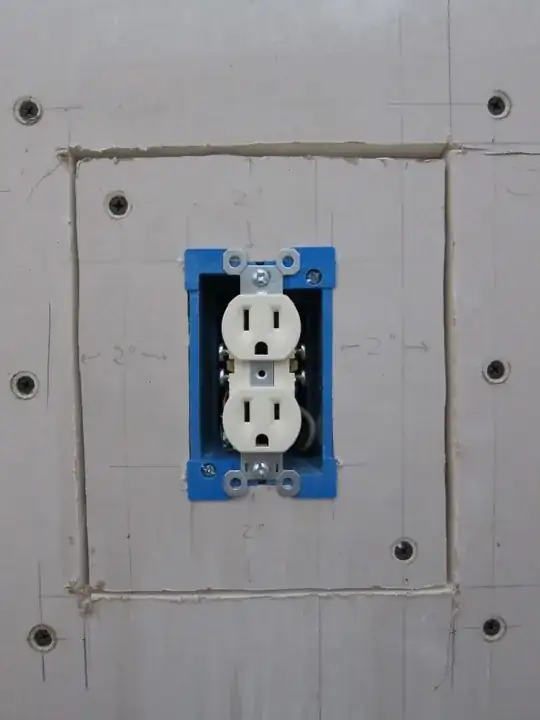

First, I cut out the smaller hole for my outlet. Then I cut out the entire section 2" around the outlet hole.

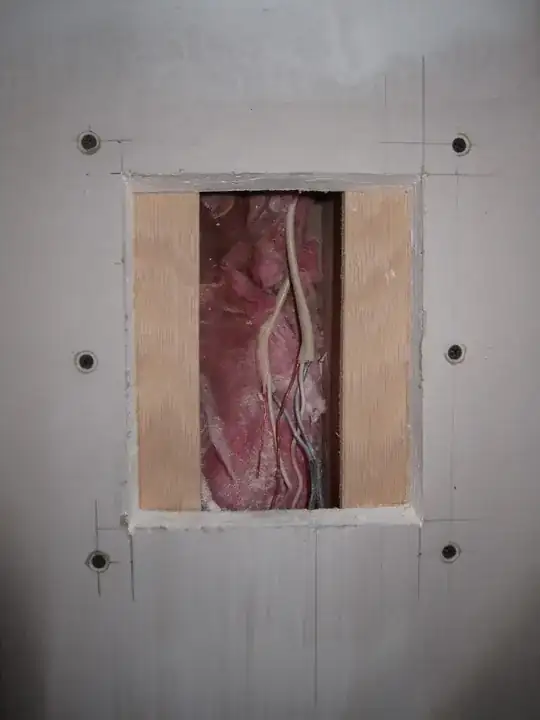

I installed some support boards on either side of the opening.

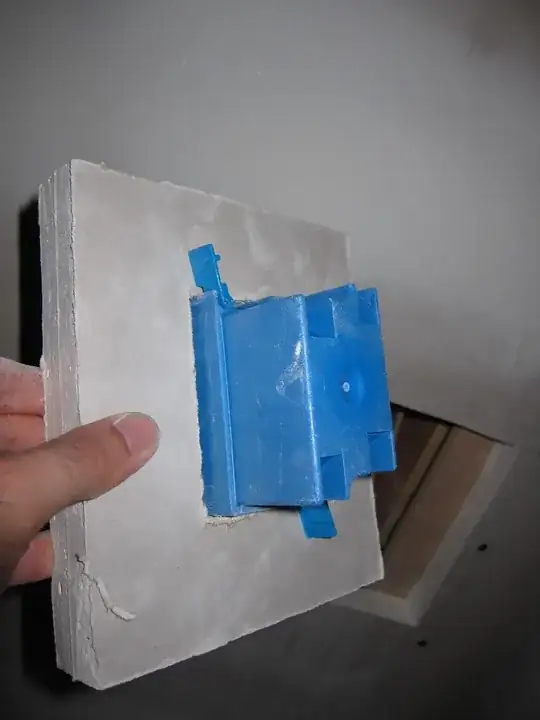

I used an old work box with adjustable flanges and installed it into the cut-out.

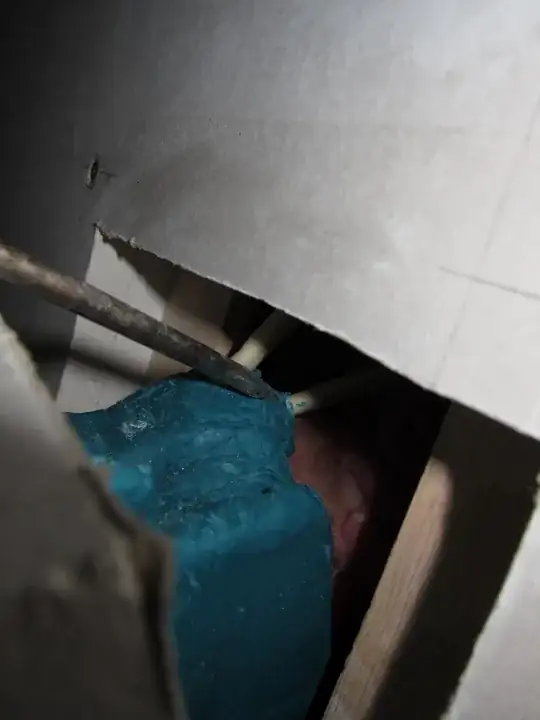

I then covered it with my acoustic putty (QuietPutty) and left an opening for the wires. Looks like some kind of alien organ, doesn't it?

I ran the wires into it and then packed the putty tightly around the wires for good measure. A flathead screwdriver worked great for packing and manipulating the putty.

Finally, I placed the section into the wall and screwed it into the support boards. My pic only shows two screws, but I actually screwed in all for corners.

If anyone else can think of a better way to do this, let me know because I am about to do it again, but this time with 5 outlets, one of which is a two ganger.