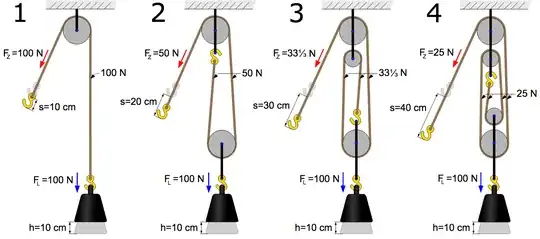

I'm trying to find some kind of clever workaround to engineer a solution to the fact that a typical pulley can't reduce both distance and weight.

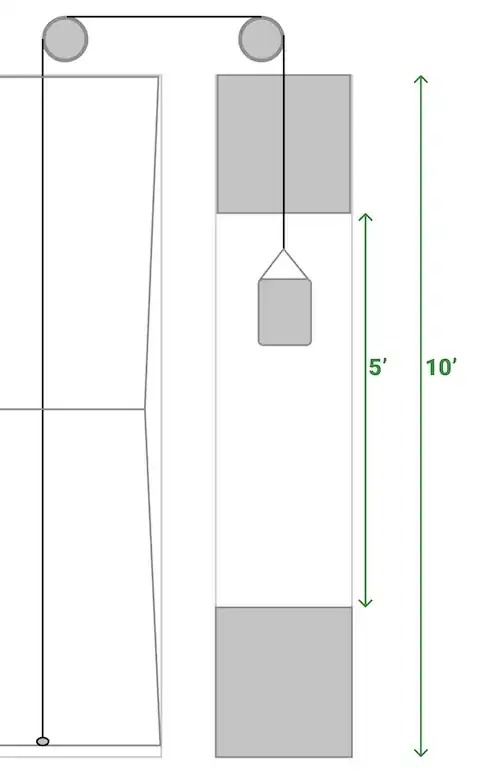

I am designing a counterweight system for a hangar door (folds straight up to open, unlike typical residential garage doors). It needs to have a pulley system with counterweights that exactly equal the weight of the door so it can be opened to any height and stay there. Due to constraints in my wall between the studs, the counterweights (buckets full of sand or water) only have half the vertical distance as the door, and I don't have enough physical space to put twice the weight of the door.

I'm trying to come up with a configuration that will allow me to overcome one or the other of my two problems: e.g., either find some way to get more distance out of the distance I have available or get more weight into the space than I have available. I don't mean in a breaks-the-laws-of-physics sort of way. I'm looking for some clever engineering solution.

For the sake of thinking about this, imagine the door weighs 100lbs and each bucket of water weighs 10lbs. The door must raise 10' but there is only room for the bucket to go 5'. There is enough room in the wall for 10 buckets but since they have to stack, every bucket you add reduces the distance available to travel: 10 buckets wouldn't have room to move at all.

Edit: for those who think I'm just trying to cheat on homework, here's a photo of me actually building this (prototype):