You are correct to hang a TV (or anything else "heavy") from a stud or other building structural member.

This provides reliable support under static and dynamic loading (think: weight, moment-arm, any leaning, minor earthquakes, vibrations from door slams), and ensures the wall material does not bend or crumble or crack over time.

When you use a stud finder or a "small-nail technique" to find structural members, it's a good start but it is not definitive.

Here's what else you might run into behind the drywall, masquerading as a stud:

- drain pipe (e.g. black ABS)

- water line

- hvac wall ducts

- drywall backing (panels or strips screwed to the back of drywall for support and alignment at seams

- junk stuffing (drywall cuttings, other building material) left in the wall to spare disposal costs or to provide acoustic insulation.

I have seen screws from electrical wall mount boxes penetrate into PEX water line behind it, garage shelving installed into ABS drain pipe, etc..etc... None were obvious mistakes at first sight. But over time they became a major headache to discover and fix.

Do not assume that anything critical in the wall is protected by an impenetrable metal cover. And if you are in a multi-dwelling, who knows what service lines are in the walls, even in your unit's inner walls.

When I install anything onto a wall stud or ceiling joist, and I want to make sure it's supported by building structure and not any thing else, this sort of summarizes my approach:

- start with a stud finder, ensure you detect the stud consistently at different heights

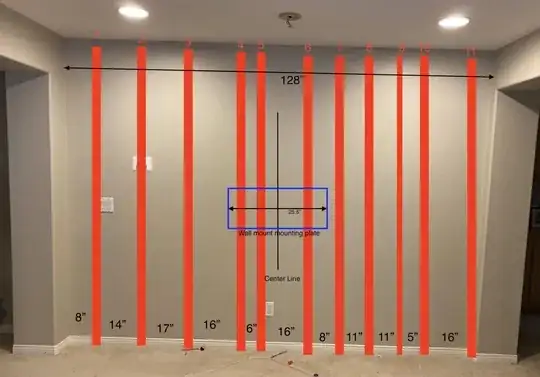

- confirm spacing with other neighbouring studs (as you have done), usually 16/24in horizontally for studs, or 24/48in vertically if there is horizontal strapping in an outside wall. Stand back and look at the larger picture, does it makes sense that there's a stud there?

- what is in the room above or below? Could it be drain or water or hvac?

- skim the wall with a flash light (e.g. from your cell phone), to spot blotches or bumps that hint at drywall screws. If it's a stud, the screws align top to bottom.

- drill an inspection/confirmation hole, perhaps 1/4-in diameter, and visually confirm it's a stud. These holes are easy to fill if you missed, and if it's confirmed to be a stud the hole gets covered by the bracket anyway.

- For more critical applications, e.g. a hanging chair, or a very heavy extension wall mount requiring more than a #8 screw, I drill a larger hole, perhaps even 1-in for better confirmation, to ensure the mounting fastener is centered in the stud. Alternatively I install a bracing panel first to cover more studs, just in case some of the spotted wood is not a stud.

- Pray, sweat, and eventually sell the house

Do not screw more than 1-in deep behind the drywall: most lines, but not all, are at least 1.25in away from the stud edges. If you need more support, apply more fasteners.

To your question about stud spacing, it can vary for many reasons:

- usually it is 16-in or 24-in: this makes it easy to "panel" drywall boards (a.k.a sheets or gypsum wall board), since their 8feet or 4feet lengths are multiples of 16 or 24-in.

- studs can be doubled, with zero spacing or 1..2-in spacing, for more support, e.g. around stairs, windows, other openings, walls in the room above,...

- stud-lumber can be used as backing, to provide backing for the drywall panels if the seems do not align with the existing framing: dimensional lumber (stud lumber) is nailed/screwed to another stud to make it "wider" behind a drywall seam. It could provide good support for a mount, even if it does not reach the full length from the top to the bottom plate.

- it provides support for something on the other side of the wall (a Tee-ed wall, a shower door etc...)

Good luck! Luck helps.