I have an enclosed cargo trailer. I need to install some rivnuts in the roof beams from the outside of the trailer. The aluminum skin of the trailer is attached to the steel tubing framework using some sort of adhesive. The result is that the aluminum is not directly against the steel tube. When the rivnut is installed, the deformed part of the rivnut ends up between the aluminum skin and the steel tube instead of inside the steel tube. This results is a much weaker anchor.

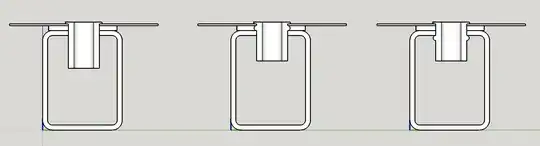

The following pictures shows the problem:

These are three different cross section drawings. Looking at the left one you can see the aluminum skin on top and the 1" wide x 1.25" tall steel tube. Between them is the layer of adhesive. I have no access to the underside of the steel tubing (which is why I am trying to use rivnuts in the first place). Removing the adhesive is not an option for several different reasons.

The rivnut is just placed into the hole in the left cross section.

The middle cross section is the result I am getting after compressing the rivnut in place. Note the compression is happening where the adhesive is.

The right cross section is the result I wish to get with the compression inside the steel tube.

The tool I'm using to install and compress the rivnut is little more than a big nut on a grade 5 bolt.

How can get the rivnut to install as shown in the right-most cross section shown in the picture? Would a different/better tool work?

The nut on my installation tool has a slight lip on it about the same height as the flange on the rivnut. It seems that if the nut had a taller lip on it (the same as the thickness of the aluminum skin, the adhesive, and the wall thickness of the tubing) then it might work.