I have a Bosch PSB 650 RE hammer drill, with a keyless chuck:

The chuck mechanism involves a button on top which, when pressed, allows the chuck to be tightened or released, rather than just rotating with the bit.

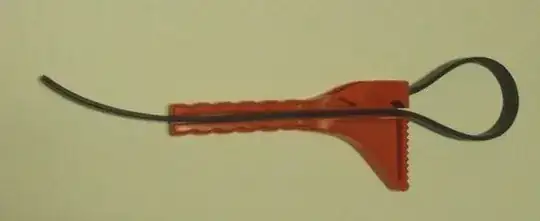

The other day I did some drilling with an 8mm masonry bit (in hammer mode); and after drilling - the chuck would not release. I applied as much torque as my hand could stand, until it was quite sore from the friction against the plastic.

My question: How do I release the bit from the drill?

I'm hesitant to try pliers or a vise grip, worried I might just file down the plastic and make a bad situation worse.

Notes:

- The chuck was not overtightened - just the usual tightness. So this related question is not quite my situation.

- I'd rather save the drill bit than break it; and would also not want to damage the chuck jaws.