I'm interested in replacing an existing outlet (in a wall that's finished with drywall) with a two-gang duplex (four outlets total), using an "old work" box. This box is located in the garage, so I'd like it to be sturdy.

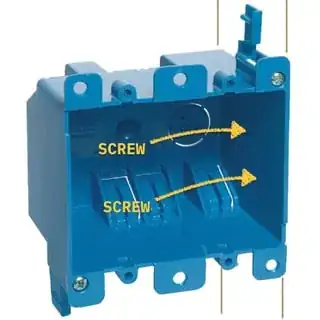

Is it considered good practice to screw the box sideways into the stud?

It appears from another forum that this might violate electrical codes. In the US, where I am:

NEC 314.23. Supports. (B) Structural Mounting. (1) Nails and Screws. Nails and screws, where used as a fastening means, shall be attached by using brackets on the outside of the enclosure, or they shall pass through the interior within 6 mm (1/4 in.) of the back or ends of the enclosure. Screws shall not be permitted to pass through the box unless exposed threads in the box are protected using approved means to avoid abrasion of conductor insulation.

If so, is there a better way to support old work boxes than just relying on the drywall tabs?