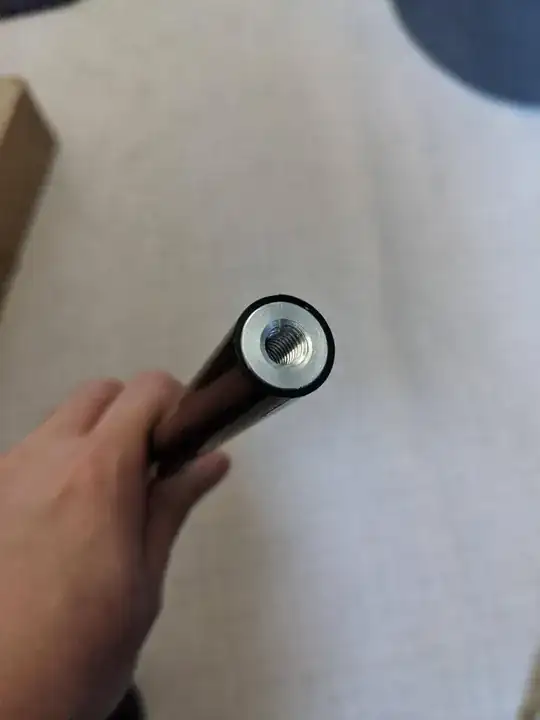

I have a metal rod with these threaded female connectors on each side. I'm hoping to cut the rod down a bit to shorten it but still keep the female connector on the side i cut. Is there a way to remove and reinsert this? I'm not sure how it's attached - I got it off amazon as a camera arm.

3 Answers

Cut the rod to the desired length. Then get a rotary tool like a Dremel with a cutoff disk. Cut the tubing that holds the insert lengthwise down to the surface of the insert. Make three or four cuts. Then pry the tubing apart with a slotted screwdriver, freeing up the insert. Slightly chamfer the inside edge of the shortened length of tubing and tap/pound the insert into the tubing.

- 89,902

- 21

- 80

- 214

A bit of lateral thinking:

- Leave the factory inserts at the end of the tube alone.

- Cut a section out of the center of the tube.

- Purchase a set of matching threaded inserts and a short length of all-thread with matching threads.

- Insert a threaded insert into each of the newly cut ends, holding them in place with epoxy.

- Screw together to make a shorter tube of the desired length.

- Add epoxy to the threaded rod for a (mostly) permanent installation.

- Leave loose for a tube that can pack down into an even smaller space for travel.

- 48,261

- 26

- 101

- 206

If you are willing to risk destruction of the item, heat may serve the purpose. As you wish to shorten the tubing, cutting off the threaded portion will prevent the remaining desired length from being damaged.

It's possible the insert is secured with what is often called Loctite™ and more generically called anerobic thread adhesive. The red version is nearly impenetrable once cured; only heat can break it loose. Secure the insert with a suitable bolt secured in a suitably immovable vise or similar. Consider to also add a locking jam nut on the securing bolt; see below.

Applying heat with a heat gun is probably more controllable than using a flame-based heat source. According to the Loctite™ web page, 500 °F / 260 °C is the release temperature. While heating, consider to twist and pull on the short section of tubing which you left in place for this purpose. You could also, prior to heating, drill a pair of holes perpendicular to the axis, beyond the insert, providing for easier twisting and pulling.

Once removed, thorough cleaning is indicated, as you'll want to use red thread locking adhesive for the replacement. You should have noted the approximate temperature at which the paint started to blister and consider that when heating the remaining tubing into which the insert is to be, well, uh, inserted. Place the insert in a freezer until frozen, or use dry ice for even lower temperatures. I don't know how red thread locker will handle the dry ice temperatures. Loctite's ™ web site says cold temperatures will slow curing time, but does not indicate any problems related to low temperature. I would not be surprised if the liquid freezes on contact with metals at dry ice temperatures.

This may be overkill, if the insert is not held by adhesive means. If thermal methods were used, the same method could be used to replace it.

Check also that mechanical crimping is not in evidence. If so, rotary grinding tools are indicated, aka Dremel™.

You already know the insert fits, so it should not take much convincing.

- 11,958

- 2

- 21

- 35