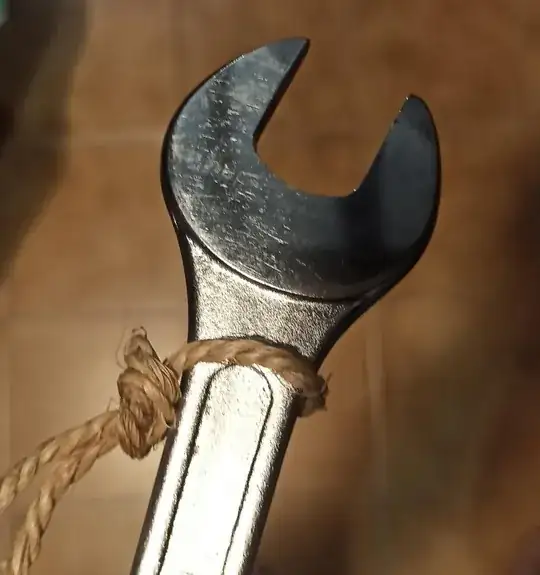

I have a couple wrenches that came with my mini air powered die grinder. I want to put a hole into the top so that I can attach a wire or string so I don't lose them.

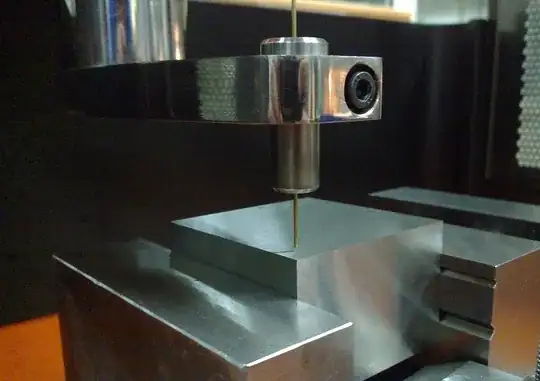

I used a punch to put a dimple into the wrench. I am trying to drill a pretty small hole maybe a bit bitter than 1/8". I put a cobalt drill bit into my drill press but it just doesn't seem to make any progress. I don't have a cutting liquid - was thinking of getting one. The wrenches are probably 1/8" thick.

Any other thoughts? What are the best bits for drill metal? What type do they use in heavy industry to drill through hard metal? Carbide? I probably have the drill press going too fast but I got it used and have never adjusted the speed. Given the size of the hole I am trying to drill it just seems like I shouldn't need the perfect setup to get a hole.

I adjusted the drill press speed to 620 rpm ( the slowest it can go - it was set at 3100 ) and I tried using a new cobalt bit with some spit on the wrench I had not previously tried to drill but it didn't seem to make any more progress than my previous attempt. I have some cutting oil and the HI-Molybdenum M7 Drill Bit Set on order so either I'll give those a try or next up I might try diamond or carbide bits.

I tried cutting oil - oatey 30201 -, setting the drill press at 3100 rpm, using a new cobalt bit, using a new spot and apply significant downward force - ending up breaking the bit.

I used my MAP torch to heat one of the wrenches to red hot and let it cool over night. The next day I used the same 3100, new cobalt bit, cutting oil and similar force. The drill bit went through ! You can see the line of the heat on the wrench. I didn't get around to trying a few of the other options yet. I'll probably give the diamond option a try on the wrench I haven't heated. Nice to have more than one trick in my bag.

Thanks for all the suggestions! I feel like I used a bit from each answer.