I'm a DIY'er doing a complete to the studs remodel. I'm getting tripped up on a minor detail that I would prefer to get right. My goal is to get the dryer vent pipe penetration properly flashed and installed.

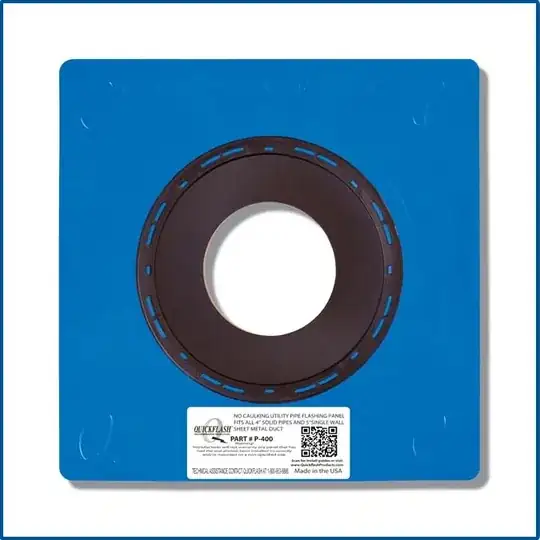

I am getting ready to call for the stucco contractor to lathe in prep for stucco. My question is what state do I leave the dryer vent penetration at before lathe & stucco? I don't want to come back and cut it in after stucco because I want the penetration properly flashed at the sheathing & WRB. Because the actual dryer box vent and pipe (image below) that installs from the outside after the fact needs to be slipped OVER the last piece of vent pipe coming out to the end of the wall, it seems that if I flash and stucco a piece of 4" vent pipe hanging out of the wall, then trim to proper length after, I won't be able to push the vent hood and pipe over the last section of vent pipe as desired. I feel I'm missing something? How is this normally done?

The images below are the components I'm using.

I have 1/2" sheathing on 2x4 stud exterior walls with a Tyvek HomeWrap. I'm using 4" rigid for the dryer vent.