You'd use aluminum

That is the main takeaway. Continuing to "bump" copper wire larger and larger and larger is just crazy. Because there are 2 costs to wire: the insulation and jacketing which is complicated stuff, especially for outdoor wire; and the metal of the wire. Above about #12, the biggest part of wire cost becomes the metal, and that's where aluminum's 12:1 cost advantage over copper really comes into play.

You can buy #2 aluminum (90A nominal) for the same price as #10 copper (30A nominal).

In 120V-land it would be wise to bring a fourth conductor

It will cost 33% more at most, but give 4 times the practical power. It will allow you to bring over both poles (phases) of 120V power, giving 240V also. Instead of 15A@120V you have 30A@240V. Keeping the neutral wire allows you to place loads on either phase, and if you balance them, you could run four 15A@120V loads for the same voltage drop as 1.

Alternately, use transformers

If aluminum wire doesn't bring price into line, you would be better off using 2 transformers to step up the voltage to the highest the wires will permit for the long-distance transmission. For instance, bumping 120V to 600V (5x) will result in 25x improvement on voltage drop, i.e. 1/25 the conductor cross section will provide the same drop.

Also, because you are carrying only one phase, you only need 2 conductors + safety ground. That allows you to derive 120V and 240V at the far end, since the transformer can be tapped for that.

Crunch the numbers, sometimes this makes sense.

And you bet you can taper.

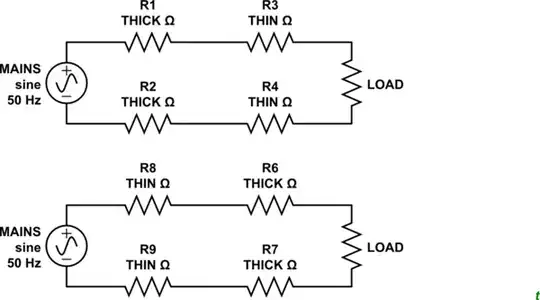

You'll have to, because the switches, receptacles and breakers intended for 15-20A circuits will not take #2 or #4 wire, and many are not rated for aluminum either. So you will need to splice down to smaller wires as appropriate. If you are computing voltage drop, you need to then compute voltage drop on each segment individually, although very short runs under 10' aren't worth calculating.

For splices up to #6 wire size, use "MAC Block Connectors". Above that you need to move into the more expensive Polaris connectors.