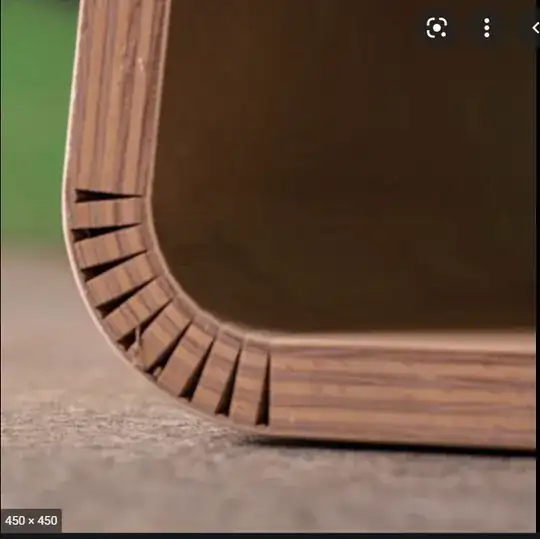

I've been researching for some time how to cover a curved stair riser that had been previously tiled. I wasn't pleased with the look of the tile, so I removed it and sanded back the mastic before veneering. However, the veneer was too thin and it left a significant gap between the tile and the riser. I would like to cover it with a 1/4" or bigger plywood (or some such material) so that I can paint the risers to match the rest of the staircase and cover the grout. You can see there is a very sharp turn on the left side of the riser. I tried kerf cutting some 1/4" plywood and found it impossible to get the plywood to bend along such a tight curve.

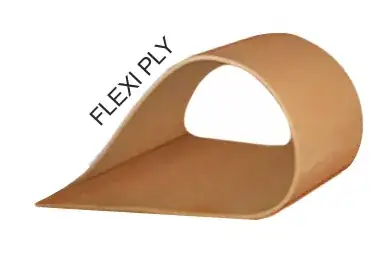

Does anybody know of a good way of doing this? I've had "bendable plywood" recommended to me, but I don't know what that is or where to get it. Lauan plywood turns up as a result, but it's not available near me.