Can I?

Sure, why the heck not?

Will you like the results?

Maybe, maybe not.

As you've noted, if you're going to DIY a jigsaw puzzle, you'd usually cut it with a scroll saw. That's because the blade of a scroll saw is much more fine than that of a jigsaw. It will give you much smoother cuts in addition to being able to make tighter curves. The tight curves may not be that important to you, but you may not be happy with the rough cuts you get from the jigsaw.

You'd probably have to sand not only the top/bottom of the plywood to round over the corners to avoid the possibility of splinters/cuts, but you'd probably also want to sand the cut surfaces themselves to make a nicer finish. When you've finished with the sanding, you probably won't have tight fitting pieces anymore. Actually, since the jigsaw blade is very thick (in comparison to a scroll saw blade), you won't even start with tight fitting pieces.

IF, however, your goal is primarily to gain experience with the tool and you don't care that much about the final result (i.e. you'll be happy even if it's a fairly sloppy fitting puzzle), then by all means go ahead and do it! You're gaining experience and learning, and there's nothing wrong with that!

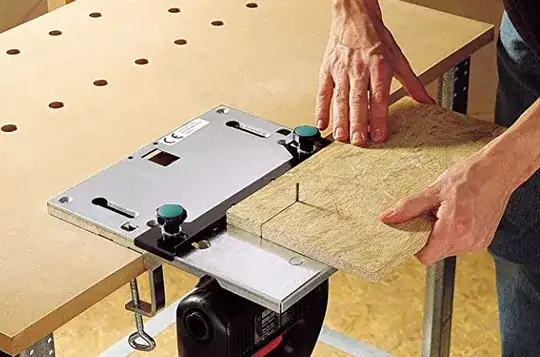

use clamps to hold the jigsaw tool in place on my workmate, with the blade going through the gap between the top parts

Generally a bad idea, though I've seen it proposed on many YT videos. You'll have to reach under the bench to turn the jigsaw on and lock the motor on. Does yours even have a trigger lock? Once it's locked on, you have to reach back under the bench, reaching more or less blindly, for the trigger to unlock it. It's possible to get your hand into the area where the blade is moving and cut yourself.

If you have to turn the saw off in a hurry because the blade is jamming, or the wood is moving out of control, then you don't have a quick, safe way to reach the power to prevent blood loss. Never a good plan.

I've got some welders gloves I could wear for a bit of protection.

Welding gloves won't offer much in the way of protection against a jigsaw blade. It'll cut through even thick leather pretty darn quickly. It will give you an extra fraction of a second before the blade reaches flesh, but not much.

In general, it is recommended to not wear gloves when using power tools (with the possible exception of cut-proof, chain mail gloves like meat cutters wear). The material in the gloves doesn't offer much protection against the sharp bits (noted above), and they have the added bonus of tending to get caught up by the sharp bit and pull your hand in toward the sharp parts. Avoid gloves when working with power tools.