In another answer it was suggested that Panel Sheathing Clips between sheathing panels in a shear wall "will add a great deal of shear resistance at a minimal cost."

Is this true? If so, why?

I could be wrong and will be glad to use them if it makes sense to do so, but it seems that such a clip would be moot or even detrimental because of the following:

- This is an indoor wall so shrinkage/expansion from moisture will not matter.

- The sheathing will be nailed 2" apart all the way around the border and into frame blocking, so the clips will not provide any alignment.

- The clips might offset the sheathing by their thickness causing a deflection in the sheathing material when pressed against the framing/blocking by the nail schedule.

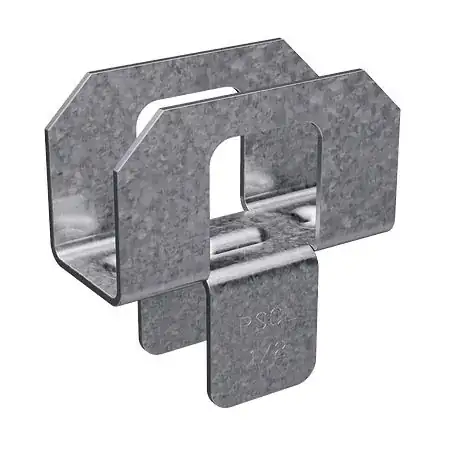

The clips look like this: