If you have a rotary tool, like a Dremel, you can use those cutting disks and have a much cleaner cut. It's the same principle, but with greater control and a finer abrasive to leave a smoother cut.

You could also try an oscillating tool. If you happen to have a carbide blade, or simply one with small teeth (or possibly an abrasive blade), you'd likely get a better cut than a grinder. As an aside, I bought an oscillating tool just last year and I don't know why I waited so long. It's absolutely worth the cost, it's just so darn useful. I'd say I don't know what I did without it, but I actually do know just how frustrated, bruised, cut, etc. I was doing things without it. Not to mention how time consuming it was trying to find ways to cut things without one, and the tools and blades I broke using them incorrectly or awkwardly.

If you want a really clean cut, you could try a sharp wood chisel and a hammer, with a wooden backer for the cable to sit on. You'll likely need to sharpen the chisel again afterwards, though.

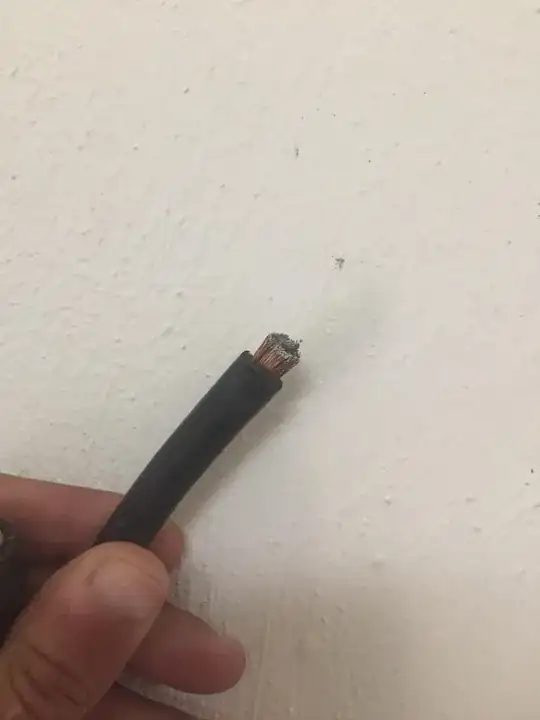

Regardless what tool you use to make the cut, if you aren't cutting through the insulation, wrap the cable in strong tape to hold the smaller wires in place and make your cut through the tape. This way the strands cut, instead of bend.