When we PVC-weld an ending with a flexible pipe, the pipe is usually very snug in the ending. The weld makes the bond permanent and ensures that no fluid can pass through.

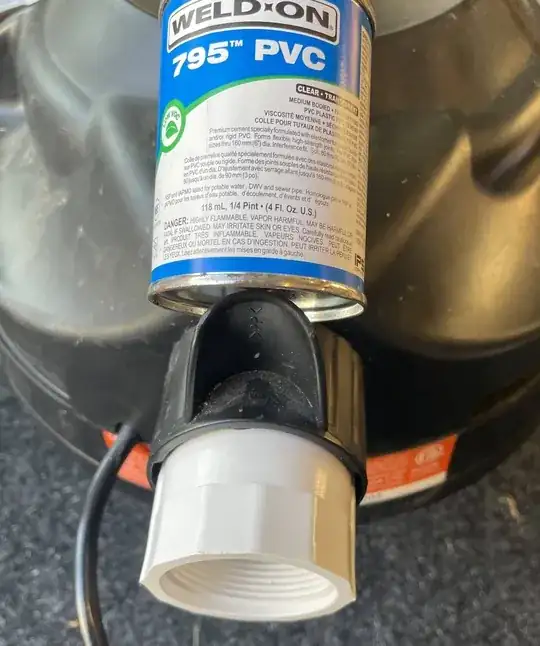

I'm trying to double-purpose a shop-vac to become an air pump. The ending pictured (white plastic) is not quite snug in the shop-vac air outlet. It wobbles ever so slightly—to the tune of perhaps 1 mm on each side (1/32" or thereabout).

I'm concerned that the welding product meant for this sort of joint will not quite cure while filling such a big gap, that it will either fail by leaking or by not curing outright.

Will a PVC weld cure to fill 1 mm? What other bonding agent could I use as a filler before using, or in addition to, the PVC weld?