Good morning all,

I recently got into DIY and one of the first projects I undertook was to rebuild the door and frame for a small outdoor cupboard / shed on our balcony. Right from the start, I couldn't quite get the door to be straight, but it wasn't off by much. I've used European oak boards with groove and tongue, 20mm thick. I added 20mm thick and 110mm wide oak boards to the back as a frame in a ledged & braced fashion. I left a bit of space between the interlocking boards and made sure not to glue the frame to the front, using screws only. I applied three coats of clear wood stain to all of the pieces of wood used. I did not use drill larger holes for the screws than the screw diameter, as I was not aware of this advice prior to building the door. Now, I would be worried that enlarging the screw holes will make positioning the door to properly fit in the frame difficult. As it is made of oak, the door is already very heavy (for a next time, I'll consider something more light-weight!).

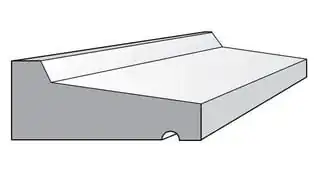

With the weather turning colder and wetter, I've noticed the door has been becoming wider: I've had to plane of a couple mm along the side to make sure it can continue to open and close. More problematically, the door has also started to warp to the point that the top left corner is almost sticking out from under the frame. It remains functional, but I specifically tried to build the frame and place the door within it so that rain water would not be able to drip on the top of the door or get in the shed proper. If it warps more, this won't be the case anymore!

I've enjoyed learning about simple carpentry work, but hope I can avoid having to make a second attempt at this door in the near future. So my question is, do you have any advice on how I can manage the warping or what I can do to improve the door design? I've attached some pictures for greater clarity.

Any advice offered would be much appreciated!

Thanks and best wishes from the Netherlands.