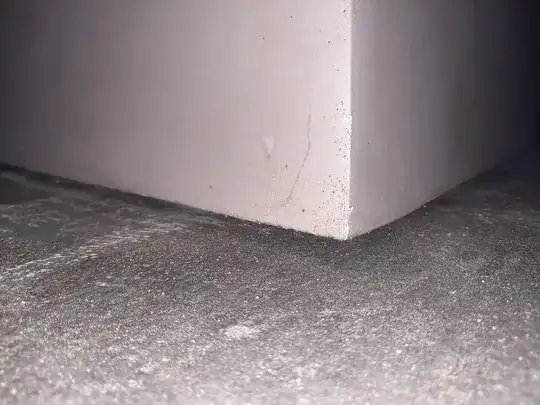

I made a concrete slab to house my concrete fountain. The problem is the concrete fountain base wobbles on top of the slab. The concrete fountain itself came with plastic shims that I put in place. However, the fountain only came with four. I was able to break them at perforated points and use more to try and put more all around the fountain. My concern is that these areas where the shims are will create stress points and the rest of the area underneath could be vulnerable to cracking. I'm including photos to display what I am working with. You cannot see the plastic shims because I tucked them underneath and they're not visible from the camera angle.

Would it be possible to use something like a foam like Great Stuff and inject it underneath the fountain in an attempt to help create a more solid contact between both surfaces and alleviate the stress that will be where the shims are located? It's less than a half inch at it's most uneven point. But given that one of these fountains will weigh about 400lb after it's filled with water I think I should do something to help prevent possible cracks in the base.