Floor flanges like you show top and bottom would actually work beautifully. Use a little lithium grease to keep things from seizing up and be happy with a robust, cheap solution. You could put a pair of cross tees on the mast with protruding nipples for mounting. 1" or 1¼" pipe would look good and could contain power and HDMI cables.

To create a swivel stop you could notch the end of the pipe and put a set screw through the flange.

I would not rely on a single bearing suspension point (as in other answers) outdoors. Even with a high quality bearing you're likely to get movement in any substantial breeze, and if your balance isn't done just right it's likely to lean.

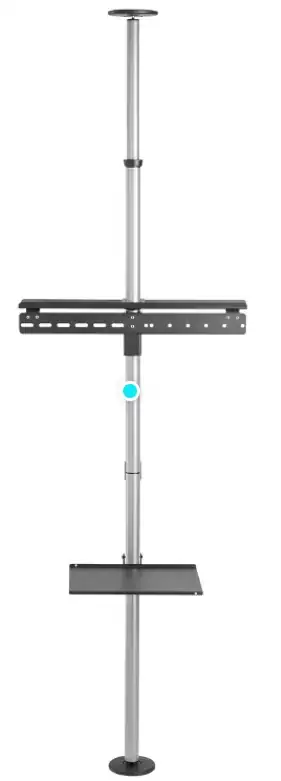

Here's what it might look like:

FRONT ELEVATION

╥ <-- floor flange against ceiling

║

║

║

║

▫═════╬═════▫ <-- cross, nipples and endcaps

║

║

▫═════╬═════▫ <-- cross, nipples and endcaps

║

║

║

║

╨ <-- floor flange against floor

If you size the vertical pipe in the center properly (with a nipple or custom cut at the store) you'll hit your VESA mount height with the crossbars. Put some holes in there at the proper width and use some plastic bushings to create a slight space between the pipes and the TV for clearance.

You can add fittings such as open tees where appropriate for cable management. If you want to get really fancy, use 90° or 45° elbows to bump the central section back so that the TV is centered between the floor flanges:

SIDE ELEVATION

╥

║

║

╚═╗

|| ║

||:║

|| ║

|| ║

||:║

|| ║

╔═╝

║

║

╨

As you do your planning, keep in mind that it's not really possible to build boxes (rectangles) with threaded pipe. You can fake it by grinding the threads off a non-critical joint, but you can't assemble it directly due to the logistics of the situation.

How did I build the diagrams? Here's your huckleberry. Scroll 2/3 down the page.