This type of floor support element is considered normally to be simply supported. What this means is that maximum shear force occurs at the supports and maximum bending moment occurs near the middle of the span. What does this mean for you? The web portion of the joist is what primarily resists the shear load. The flanges (your cracked part) are what primarily resist your bending moment.

Assuming you are located in the US, UK, or Canada and I am pretty sure most places that have licensing requirements for Professional Engineers, means that the advice the structural engineer gave you, they a liable for. You should either receive a letter or a report from the engineer stating their findings and recommendations. This documents should be signed and bear their professional seal.

In terms of the three comments you initially got, the contractor is hopefully basing their statement on plenty of previous experience dealing with the product. Ultimately they have no professional liability in the matter. If they were the initial contractor, they will not get paid to do any remedial work so they will tend to try to push it off until the warranty period expires and then not deal with you at all. There is no profit in it for them to do the work. A few exceptions might be if they know it will lead to future work, or are trying to develop their reputation.

If your contractor was just a random one you just called up to look at it, then they may be giving you good advice and trying to save you some money. They may also be basing it on their past experience where they see the time an effort to come up with a reasonable estimate usually tends to scare the customer off and winds up being a waste of their time.

The engineer that works for the manufacturing company may be biased if the advice of sistering the joist results in a sale going through them. They may also be overly cautious if you wound up talking to a more junior engineer.

The independent local engineer has little to no stake in the matter. If they say it does not require repair, they are on the hook if something goes wrong in the future. Where they might have some bias is if they get follow up work for the design of the repair.

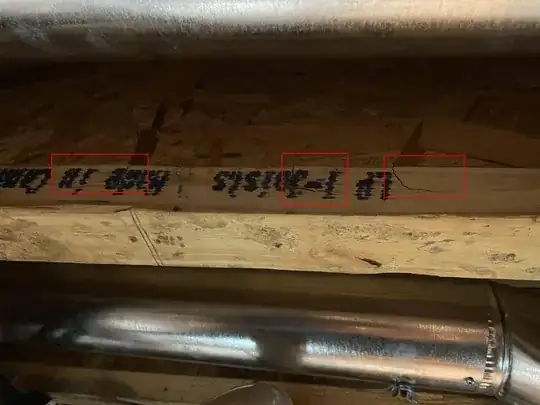

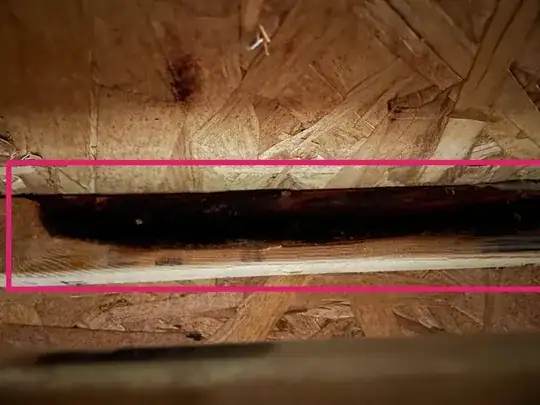

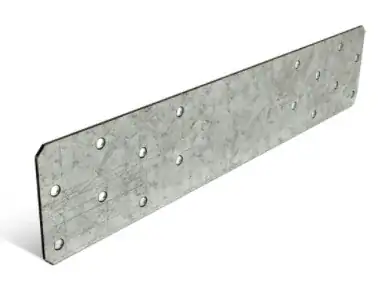

While sistering the joist will strengthen your floor, it may be overkill for your repair needs. Because most of your bottom flange is still intact and you are on a shorter span than what the joist is designed for you may still have adequate support. Alternatively if after going through the calculations you figure your joist is too damaged to adequately support the load, you may only need to add a steel plate to the under side of the bottom flange. Some joist manufactures do not support any types of repairs to these structural elements while others do. It may be as simple as adding the equivalent of something like the following Simpson strong tie part.

Ideally you would nail this in such away that is pans over the cracked areas. You can check with the joist manufacturer if this type of repair is acceptable and what their plate sizing and nailing recommendations are. Because the plate is relatively thin, it will make placing a ceiling potentially slightly easier in the future if you should ever decide to finish your basement.