I have a faucet that leaks at the valve, and I would like to remove that faucet to replace it with a new one.

The trouble is that it is mounted tightly between the wall and the sink, so there is very little space to work with.

I would like to avoid having to get the entire sink removed.

How would I remove this faucet?

The view from below:

The view from top:

It is unclear to me what I should be twisting.

Do I twist that large open ring? Against what? Faucet-base? Faucet-body?

And in which direction do I turn it?

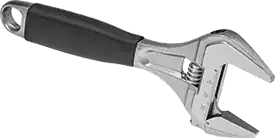

Do I need a special tool?