I have a bunch of 5/4” x 6” x 8’ severe weather pressure treated boards from Lowe’s and was going to wood glue them together and then trim it out with 3/4” x 4” pressure treated wood boards I have. I figured that would also help keeps the boards together. However all the plans I’ve seen online for barn doors seem to be inside the house and not outside and are sliding doors where mine will be hinges as it’s for a shed. Will pressure treated lumber like this work well or is this doomed to fail as the wood glue (titebond ultimate) may not work and the trim isn’t sufficient to hold together. The doors will be approximately 3ft in width and 7ft in height. Hinges will be at the top , bottom, and mid section.

2 Answers

The fact that the lumber is pressure treated isn't really a problem for you. The problem is likely related to the moisture content of the boards.

I don't know how old the lumber is, etc. but one of the challenges with newly-purchased pressure treated lumber (especially from the Big Box places) is that it's almost always wet. Very wet. Too wet to glue wet. Wet where water (or chemicals maybe?) will drip and run out of the wood fibers when you drive a screw into them.

The glue itself should bond fine as long as you provide dry, clean and flat wood surfaces to glue together. Exterior grade glue will work like a charm under those circumstances, but the right way to do it for doors (since they are subject to the stresses of being moved, etc.) is to use galvanized, stainless or ceramic-coated screws as well to hold the door together.

The problem is, especially with an outside door, because the wood is out in the elements, it acquires and loses more atmospheric moisture which causes the wood to swell and shrink more than an interior door.

Glue isn't going to really help you here as the moisture-related expansion and contraction isn't going to "play nice" with the glue joints. As the wood moves, it moves across the grain of the wood and the movement can be significant as the moisture level of the wood changes to the point that the door can tear itself apart.

At the center of the boards, the movement is less than from edge to edge. Screws, when attached through the center of the boards (where moisture-related movement is minimized) should work very well.

Tongue and groove profiles are sometimes cut into edges of the battens (vertical boards) so that they lock together and as they expand and contract, any gaps between the batten boards are dealt with. It isn't 100% necessary, but it is a nice feature. You can cut tongue and grooves with a router and appropriate bits.

Here's a tutorial that explains it better than I do.

And another one that's very good (and thorough) too.

- 6,251

- 2

- 24

- 42

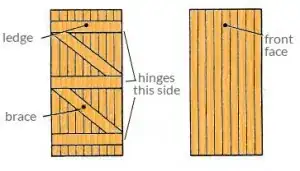

This answer is highly related and will provide many good tips on building your door correctly the first time. In particular, pay particular attention to the bits on gluing/screwing the bracing to the back. (TL;DR: do not glue the bracing to the back!)

Your Titebond III should be just fine - it's waterproof which is what you want for an outdoor project. However, from the "Limitations" section of their product page:

Because of variances in the surfaces of treated lumber, it is a good idea to test for adhesion.

Emphasis added

I went to look up "Titebond Ultimate" because I've always referred to it as "Titebond III" and wasn't sure if they were the same product or not. They are. Technically, it's "Titebond Ultimate III". Enough product promos for ya'? :)

If you let the PT lumber dry (probably 3 months, depending on your local humidity) and get a good, straight, freshly sawn (or even better, a jointed*) edge, your glue up for your panel should be just fine.

One thing to consider, though, unless you need the door to be absolutely water tight, you may not need to glue your door panel at all. Just be sure your decking (that's what your 5/4" x 6" was sold as, right?) has good straight edges, butt them tightly together as you screw your bracing on the back, then put a waterproof layer on the inside of the door to catch any moisture that makes it through and direct it back out and it should be fine.

*You can get a jointed edge with a jointer, of course. You can also use a jig on a table saw, a powered hand plane, or even a good old-fashioned hand plane. Many will argue that you will get the job done with a hand plane faster than you can set up the work on any of the power tools. Don't forget, though, that there may be sharpening time prior to hand planing and, possibly, during if you're doing enough work - they don't seem to count this into the speed comparison. ;)

- 48,261

- 26

- 101

- 206