I disagree with your primary thesis. It's quite easy* to measure to 1/32" or better accuracy with a standard tape measure, even of the heavy 25-30' variety. As a professional finish and framing carpenter I've done it many thousands of times. It's just a matter of technique.

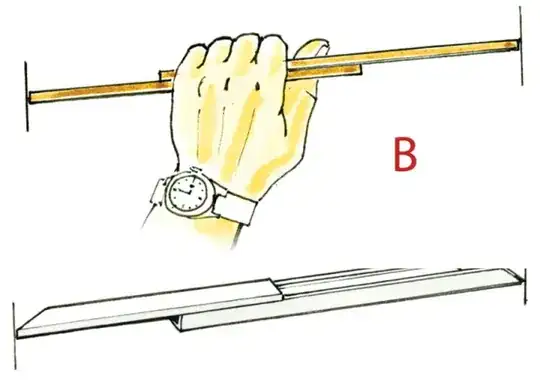

- Press the bend into the corner firmly. Even steel tapes are plenty flexible.

- Tilt the blade to one side. Doing so concentrates the force on the edge, allowing a very sharp bend.

- Read the measurement at an angle perpendicular to the blade at the center of the bend. This reduces parallax error, that arising from gaps between the blade and the surface when viewed from an angle.

- When in doubt, cut long, then cut again. Modern miter saws allow for razor-thin adjustments, assuming a quality blade in sharp condition. For a snug fit, intentionally cut just a bit long and flex the piece into place by bowing out the middle.

No need for goofy gadgets or in-your-head addition of complex fractions using the tape body size**. Both introduce error, either in mathematical rounding or in mechanical slop, and they slow you down. This technique works quickly and without a doubt even for hair-fine fitment.

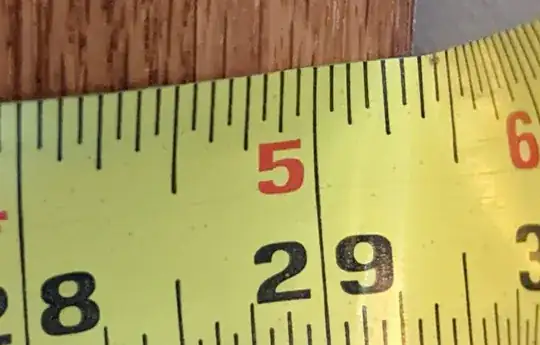

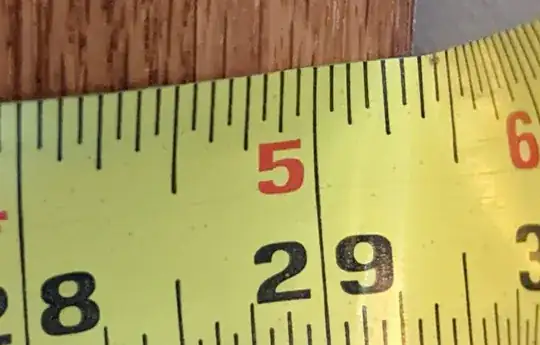

I would read the above measurement as twenty-nine and a shy three eighths, or 11/32 if you prefer.

Fun fact: Most tape measures have a bit of play in their hook attachment. This is to account for the thickness of the hook when used in either a hooked or butted manner.

* Really. It's easy. Once you're aware of this technique, it takes very little practice or effort to use it.

** Assuming you're not lucky enough to have a round-number size. Rightly or wrongly, you'd probably get laughed off a jobsite for backing your tape into a corner to get a measurement anyway. It's half a step from lifting the big end to the top of a wall to get its height.