I am trying to replace an old faucet that my 3 yo child is unable to use because of its design. I'm new to plumbing but actively reading. I haven't seen these supply lines w/o valves before. This looks like the pipes are going straight into the faucet. This is an '86 built property in Canada. I tried to look through the vanity base but didn't find a valve.

Its a fatter pipe which gets slimmer as it enters the faucet.

- Ideally I would like to add valves and then modern braided pipes into a new simple faucet. Is this doable and wise?

- What tools will I need to achieve this - I have a wrench, channel locks and the basics. I think I'll need a pipe cutter and something to smooth out the freshly cut pipe. Any solution/paste?

- What hardware will I need to purchase - if it's a 1/2" pipe, can I use any straight 1/2" valve?

- Is a modern faucet built to the same standard that modern valves and pipes are built to?

- How can I make a secure seal w/o using a soldering solution? I read this is where compression valves come in.

Pic of work area:

Pic of faucet inside:

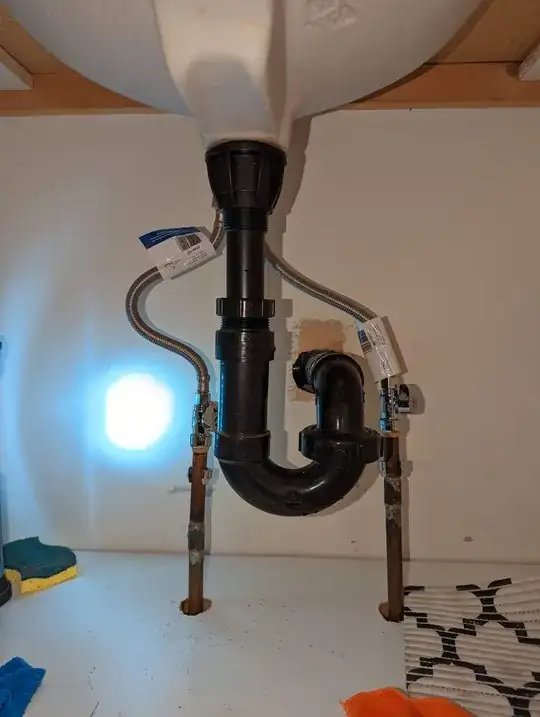

Pic of view from under sink: