I measured the maximal diameter of this counter-sunk bolt.

Note: The bolt is not parallel with the jaws, but slightly rotated so that the bolt head is behind them. Therefore measurement is not of the bolt head, just the threads.

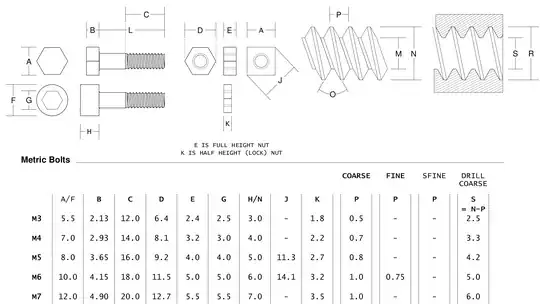

And tried to match it with the metric bolt dimension chart:

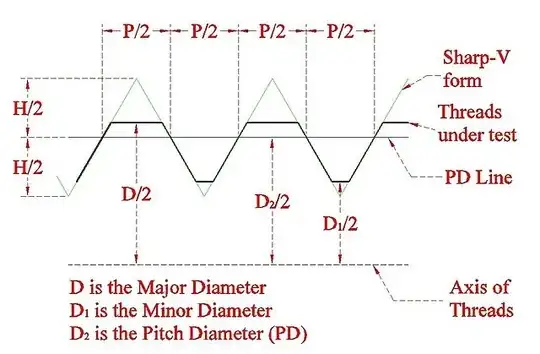

But I did not find any match. I find the difference between dimensions M,N and R,S to be mysterious and suspect that the answer to my quandary is hidden therein.

My guess is that this is an M4, since the diameter without the thread could be 4mm and perhaps in some countries the standard specifies the inner diameter instead.

I am almost sure this is a metric bolt, since it is from a EU-made machine.