Taking the cover off my electrical panel, I notice white flakes primarily on the hot bus bar just after the main breaker and under some of the individual breakers. The breakers I have removed for replacement show no problems on their conductors (they are being replaced because of circuits being replaced, I figure why not spend a few extra bucks on renewed critical safety equipment).

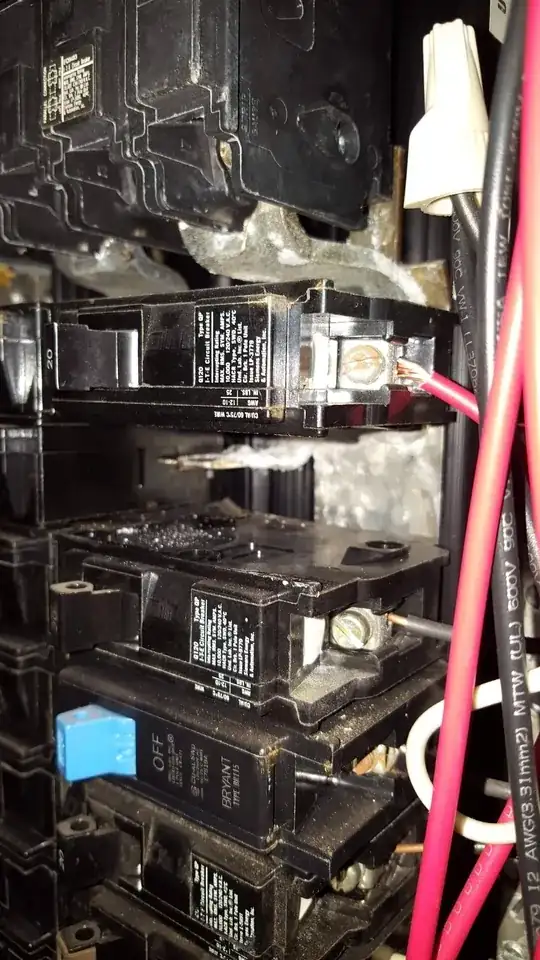

Are these white flakes corrosion? A home inspector did not report any sign of corrosion or moisture in the service panel, but this is subtle. That said, these white flakes are visible on the hot bus bar under the main breaker, as in this photo:

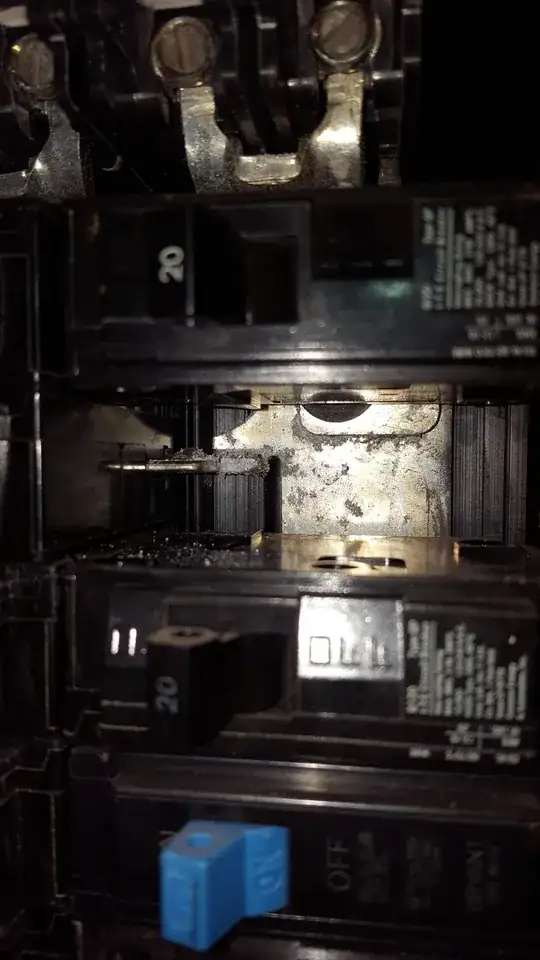

Here are two more photos showing these white deposits under a breaker that was removed:

One other breaker was removed and had less but still some of these white deposits on the hot bus bar.

Is this corrosion, indicative of a moisture issue? Is this a safety hazard, or just something to prevent from getting worse? In case it is relevant - outside the house on the other side of the service panel, the electric meter box does show signs of rust and we need the utility company to come take a look at that.

For context, this is in a temperate climate far from coasts, on a house that is about 60 years old and otherwise seems well constructed and maintained. The house is basically all electric, with baseboard heaters and an air-sourced heat pump, electric stove/oven, electric water heater, and electric well pump.