I have a 25kW liquid cooled Generac for whole house, using transfer switch RXSW200A3 (200A, service rated). Is there a way to get a "dead time" before the transfer back to the utility source when it comes back hot? I'd like at least a tenth of a second dead time (longer fine too) so I can avoid the out-of-phase kick in the face to my motors/compressors and to the generator itself.

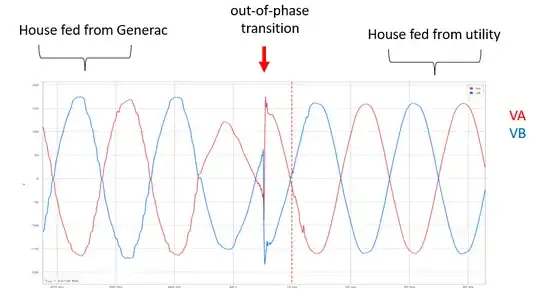

I have an SEL-735 PQ meter on my house and captured this couple days ago. We had a power outage and were running on the Generac. I happened to be outside when I heard the transfer switch "thunk" and my outside HVAC unit fan started making a sound like a stick had been stuck into the fan blade. I turned it off and upon restart it was fine. But, out-of-phase closing is a cumulative damage - it will take life off of motors etc.

I have gone through the manual on the transfer switch and I don't see a way to get a dead-time (I have RXSW200A3). My dealer says that the Cummings machines he has put in have a transfer switch that does have the dead-time ("break before make" when the utility comes back) and it is around 0.1 seconds. If I can't find a way of getting my present setup to have dead-time then I'll go the route of replacing with a Cummings (will have to convert my 4-wire Generac control wires to 2-wire but that is apparently doable).

Anyone know how to adjust RXSW200A3 transfer switch (or Generac controls) to give the much needed dead-time?

thanks, russ

UPDATE 7-12-2022: Based on @Jasen and @Gil input I now see that in is indeed a "break-before-make" switch action, but the out-of-phase transition is still present since the voltage on the induction motor load (compressor) cannot decay to zero immediately due to trapped flux in the rotor.

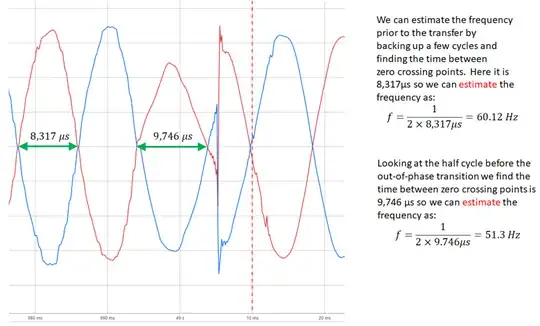

As soon as the Generac is disconnected (but prior to utility closing in) the frequency drops due to the induction motor slip. In this case the slip was around (60.12 - 51.3 = 8.82 Hz). You can see this (and I suspect that is what clued @Jasen to it) as the time between zero crossings gets stretched out. This is an immediate response to the induction motor being disconnected from the source.

The decaying voltage of the induction motor is a voltage source that is slowing down and reducing in magnitude quickly - but not fast enough to avoid the out-of-phase transition. Because this voltage is not in-phase with the utility the effect is that when the utility closes in these 2 voltages are additive (based on their phasors amplitude and relative phase position). So, the voltage across the motor may be higher than rated. A rule of thumb many designers historically used for a maximum momentary voltage applied to a motor is 125% of rated. This applies equally well to single-phase motors as three-phase.

Question: As I understand it, when my thermostat (Honeywell th8321wf1001) loses AC it causes a 24 V contact to dropout and disconnect the compressor from AC. When power comes back there is a delay before it re-energizes that contact to reapply AC to the compressor (e.g. 5 minutes). But, what I need to know is - how long does the loss of AC need to be to ensure that contact dropout occurs and my compressor is disconnected (letting pressures equalize)? Is it a tenth of a second? Is it half a second? I'm fine with a 5 second dead-time if need be to ensure compressor is out of the way before I close the utility back in - just need to figure out how to implement this and get the dead-time I want.

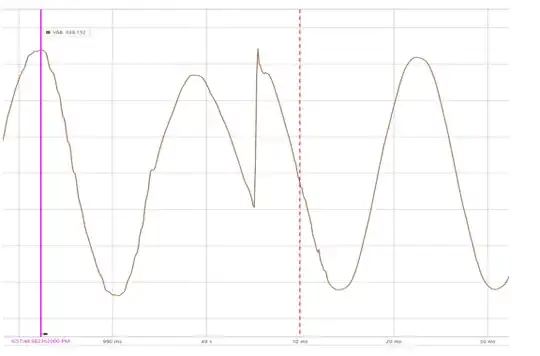

Also, below is the phase-to-phase voltage that @Gils points out will be what the compressor experiences. Remember that the voltage across the motor is this voltage +/- some portion of the residual voltage still on the motor due to trapped flux.