The other answers here are seriously flawed in one way or another. You'll see why by reading this:

https://copper.org/applications/plumbing/techcorner/prevent_corrosion_cu_tube_buried.php

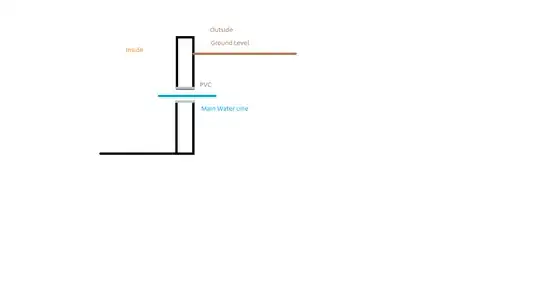

Sealing of sleeves can be accomplished several ways, although many practices which are thought to be satisfactory are actually very detrimental to the copper tube.

One such practice that should be avoided is the sealing of the space between the tube and sleeve with silicon caulk. Many silicon caulking materials outgas ammonia and/or methanol during their curing process. The outgassing of ammonia, within the sleeve, can lead to stress corrosion cracking of the copper tube, and eventual failure.

Another often employed practice that should be avoided is the sealing of the sleeve with hydraulic cement. Though no adverse reaction with the copper tube will occur, the fact that the tube is held very rigid at the location of the hydraulic cement may contribute to stress fracturing of the tube at that point. Stress fracturing is caused by overworking the tube at that point through motion from thermal expansion/contraction, movement of the backfill material by freezing and thawing, or settling of the soil or structure around the sleeve and tube by improper compaction of the backfill.

Two inexpensive and easily installed ways to properly seal sleeves, water-tight can be accomplished using Fernco TM elastomeric clamps (Figures 1 and 2 above) and electrician's duct seal (Figure 3). Both of these allow the tube to expand and contract and move within the sleeve and still maintain the water-tight seal.

It only takes one serious flaw in an approach to risk failure and water infiltration.